views

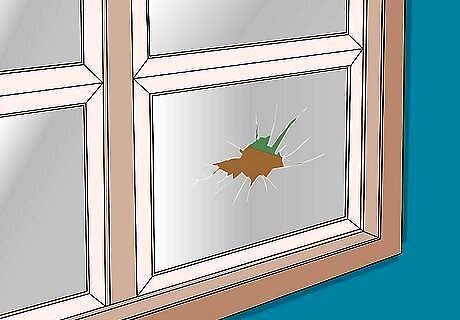

Determine what kind of window or door you're dealing with; building codes in your area will likely require tempered glass in your storm windows and doors, but you may be able to use regular pane glass for inside (not storm) windows and doors. Be sure to check local codes.

Remove the window from the casing if possible; take the door with the broken window off the hinges. Replacing the glass is far easier if the window/door is laying flat on the work surface and is clamped down, caulked side of window facing up. If this isn't possible, you can replace the glass in place; make sure you have a solid footing and are at eye level with the upper third of the pane. Consider just taking the window to a local hardware store and let them replace the glass. They tend to be reasonable and since they do so many windows, they tend to be fast and cheap on the labor and do excellent work.

Dispose of the broken glass. Wear protective gloves and remove the broken glass. Put it in a cardboard box or sturdy garbage bag. When all the glass is out of the frame, tape the box/bag up for disposal and mark it clearly "Broken Glass." Place the box/bag wherever your trash pickup might be. Use a wet cloth to pick up any small shards, and toss the cloth out with the rest of the glass. EXPERT TIP Douglass Brown Douglass Brown Glassblowing Expert Douglass Brown is a Glassblowing Expert based in Half Moon Bay, California. He has over 25 years of experience as a glass artist, and is the owner and operator of 2 glass blowing studios in the San Francisco Bay Area, Half Moon Bay Art Glass and Mare Island Art Glass. Douglass believes in sharing hot glass experiences with anyone who wants to learn about the processes of blowing and sculpting glass. When not teaching, Douglass creates glass art that is a mix of his takes on nature and functional glassware. He has also created the Glass Troubadours, which is a mobile glass blowing studio that hosts parties, events, and visits craft shows. Douglass Brown Douglass Brown Glassblowing Expert Wear gloves when handling cut glass. Protect yourself from injury when handling cut glass. Industrial or gauntlet gloves provide better protection than disposable gloves.

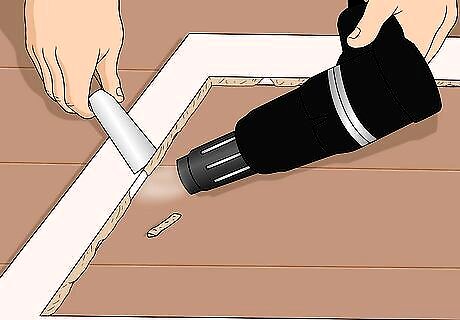

Remove any remaining old caulk with the putty knife. You may need to heat it up with a heat gun to get it completely loose. Also remove any of the old glazier's points from the broken pane; it's a good idea to save them in case they're a different size from the modern points. Use the metal brush to get the surface as clean as possible. Optional step: carefully brush linseed oil on the surfaces that will be holding the caulk. This extends the life of your caulk job, but it takes a day or more to dry, so plan your time accordingly. It is a very good idea to prime the wood with exterior primer or use exterior varnish to seal the wood. This will make the wood last decades. Without sealing the wood, it might rot in only a few years.

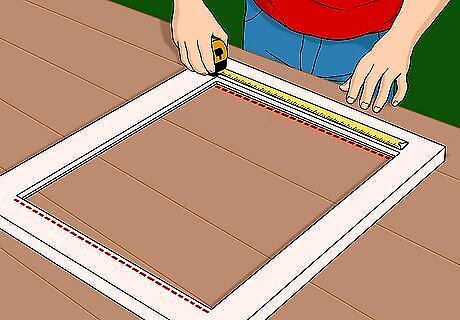

Carefully measure the width and length of the opening for the window. Measure at both top and bottom to see if the window is plumb. If the shape of the window isn't square or rectangular, make a paper template. There is a very narrow shelf-type area that the glass lays on; there may also be one side, usually the top, slotted to receive the glass. Remember, you're measuring where the glass lays, not the visual opening.

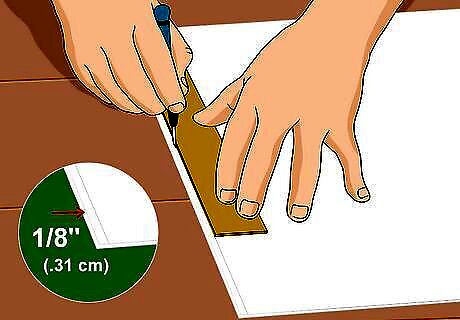

Go to your friendly neighborhood hardware store or home center and have them cut the glass. The replacement glass should fit on the "shelf" from side to side and top to bottom fairly snugly, but to allow for expansion and contraction, have the glass cut up to 1/8" (.31 cm) smaller on the top and one side. 1/8th of an inch can cause the upper piece of wood to sag over time. Using 1/16th of an inch smaller makes fit tighter and is better for supporting the wood. If you use glass the same size as the opening, it will stretch the wood and might make the window harder to fit (or leave small gaps at the corners where water will get in and rot the wood).

Insert the glass into the frame. With the frame secured to a flat surface and the bottom of the window closest to you, hold the glass at a slight angle top to bottom. Guide the whole pane slowly on the "shelves" and work toward the top. When you're just about there, carefully lay the glass almost flat, then guide it as you slide it into the groove at the top of the window. You may need to use one hand on top of the glass, the other on the bottom.

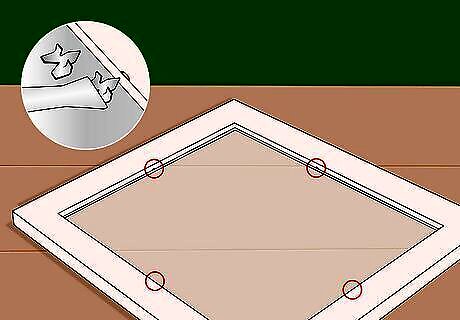

Find the spots where the old glazier points were and put in new ones.

Prepare the glazing compound. Open the compound can and put a lump about half the size of a tennis ball (use more when you get the hang of it) into your left hand (right if you're left handed). Work it until it's soft and warm. You may have to replenish the supply in your hand more than once, depending on the size of the window.

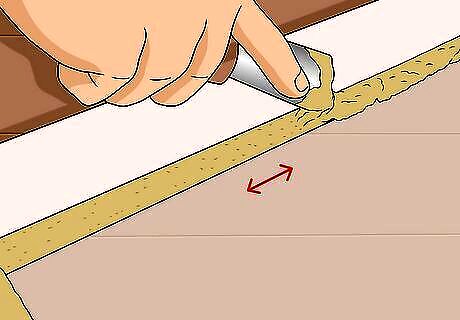

Using the flat edge of the glaziers tool or putty knife, scoop off a section of putty from your hand and spread it into the "shelf" area at any point; best not to start in a corner. Using the knife or tool at an angle, smooth the putty along the shelf. Be sure that the putty doesn't show from the other side of the window, that is, the width of your putty shouldn't be greater than the shelf width. Continue spreading and smoothing until the sides are covered.

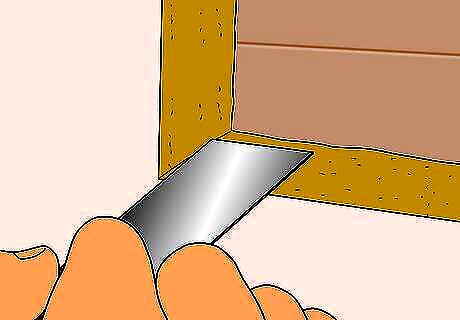

Corners. These can be tricky. Just remember that water will slide down the window and the caulking will guide the water away from the glass. You want the corners to be mitered, but smoothly mitered. Use the angled end of the glaziers tool.

Once you've finished caulking the window, allow it to cure at least a day before cleaning up any spillage on the glass. You'll need to wait up to a week for the putty to cure enough to hold paint.

Congratulations! You've now saved yourself about five times the cost of having the glass replaced by a professional.

Comments

0 comment