views

Tightening or Completely Replacing Window Screens

Remove the screen from the window, keeping it inside its frame. Usually, window screens pop out easily, but they can be held in by small clips. Check for clips before you try to remove the screen and, if present, unfasten each one. When you've removed the screen, lay it down on a flat surface.

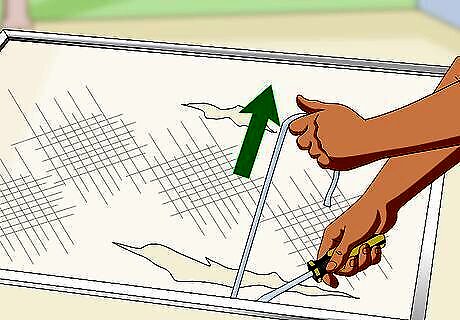

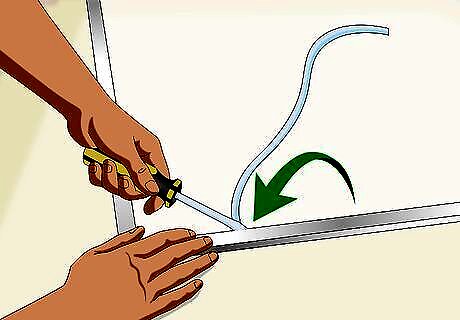

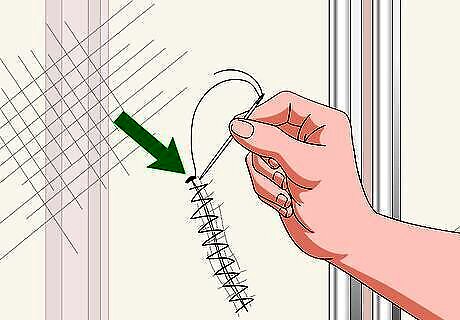

Take out the window spline. A window spline is a rubber or plastic strip that holds the screen in the frame. When replacing your window screen, you will need to remove and replace the spline as well. Use a flathead screwdriver to pry the spline out and, when it's fully removed, throw it away. Replacement splines can be purchased at most hardware or home repair stores.

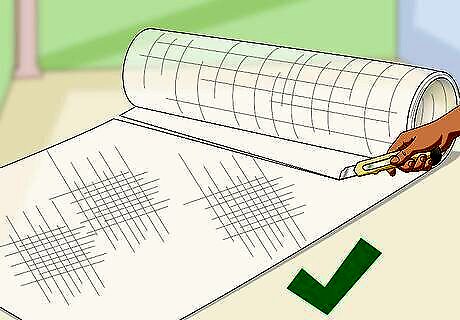

Cut your new screen out of mesh material. Purchase a roll of mesh material from a nearby hardware store, then cut it into a rectangle 1–2 inches (2.5–5.1 cm) larger than your screen. If the new screen is too large, you can always trim it with a utility knife. If you do not need to completely replace your window screen, skip this step. Aluminum mesh is popular because it is sturdier than other screen meshes.

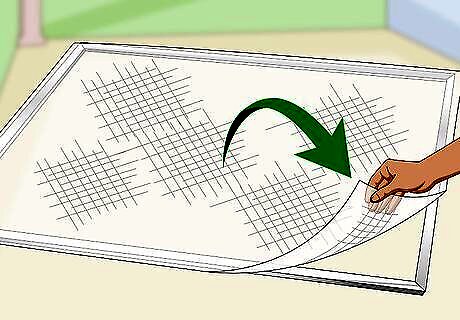

Align the mesh screen to the frame. Keep the mesh material straight and taut to ensure an even fit. Use a utility knife to cut the replacement screen to size if it is too large. The material should slightly overlap on each side but not exceed 1–2 inches (2.5–5.1 cm). If you do not need to replace the mesh screen, keep your screen in its frame and continue to the next step. Mesh material will usually curve to one side. Place the mesh in with the curved side down so it is easier to work with.

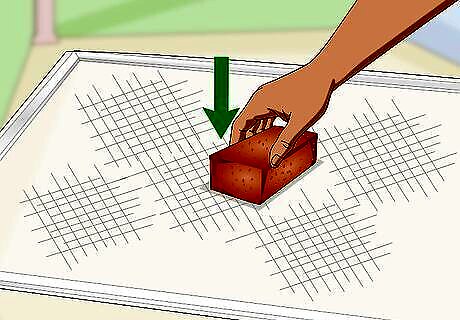

Place a brick or heavy object in the center of the screen. A brick or other heavy object will help give your screen an even amount of slack and tension. Before you place the brick on the screen, place the spline loosely around the corners of your frame and roll the 2 adjacent sides back in. When you place the heavy object on the screen, you'll be able to prevent sagging.

Roll the rest of the window spline back into the screen. When you've rolled in all 4 sides, remove the brick or heavy object from the screen. Put the screen back into the window and tighten any existing clips. If your window screen still seems loose, repeat the process again with a lighter or smaller object.

Darning Smaller Holes or Tears

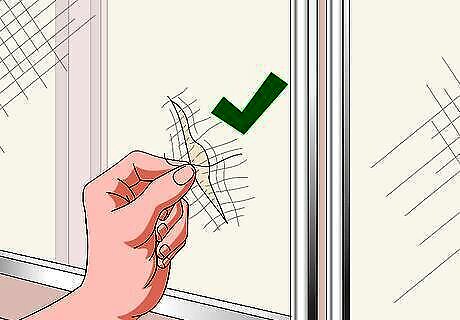

Unravel the strands surrounding the hole or tear. To prepare the screen for darning, unravel a few strands from the perimeter of the tear to use as your thread. As you do so, take care to not make the holes and tears any larger than they already are. One or two strands is more than enough. For larger holes or tears, you may not be able to darn it. In this case, you may need to patch the hole.

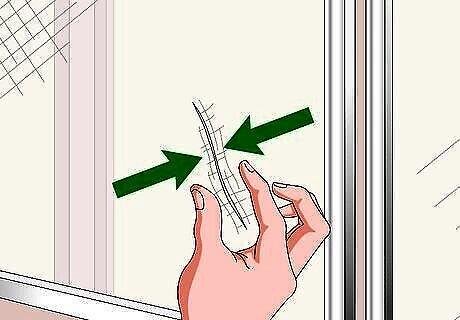

Line up the screen seams neatly. Match the two ends of the screen evenly for a neat and secure seam. There should be little-to-no space gap in the middle. If you cannot line up the two ends without leaving a noticeable hole in the middle, you may need to patch the screen instead of darning it.

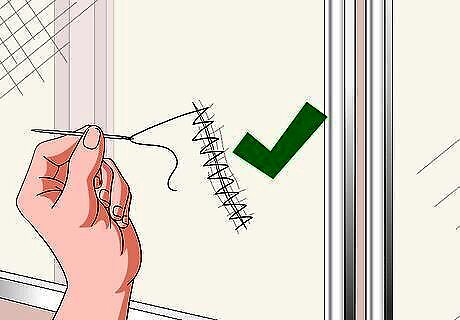

Weave the strands through the screen with a sewing needle. Once the torn edges are lined up, use a needle to weave the thread through the screen strands. If you don't have strands of screen material available or do not want to risk making the hole bigger, use a heavy-duty, polyester thread. Make the stitches as small and identical as possible. Choose a needle with a large eye that can accommodate the screen strand. If you have sewn the hole or tear and it is still noticeable, cover it with a patch.

Finish darning the screen with a securing stitch. A securing stitch will prevent the darn from coming undone. Make a small stitch at the end of the hole or tear, then stitch over it again. At the end of the stitch, make a small knot and pull it tightly to finish the securing stitch.

Patching Large Tears in Your Screen

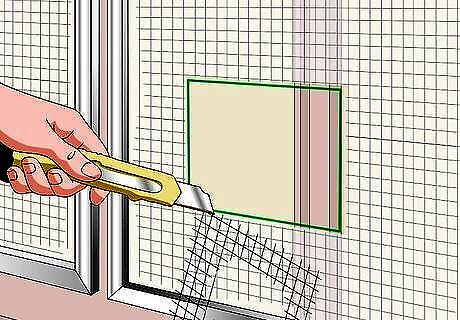

Cut the damaged area into a neat rectangle. Using a sharp knife, cut a clean hole around the screen tear to remove all irregularities. Make this new hole as small as possible to keep the repair simple. If the damaged area is already rectangular, trim the sides to make it even. If the damage takes up more than a quarter of the window screen, you may need to replace the entire screen. Leave at least ⁄2–1 inch (1.3–2.5 cm) of screen material between the hole and the window frame. The closer a hole is to a frame, the harder it is to repair.

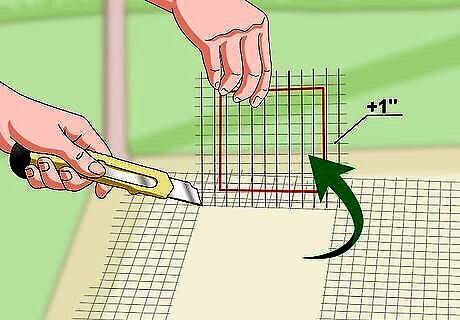

Cut a piece of patch screen material for the damaged area. The new patch should be at least 1 inch (2.5 cm) larger than the rectangular hole. Any smaller and your patch may not securely cover the hole. Measure the patch before you cut to make sure you cut the right length.

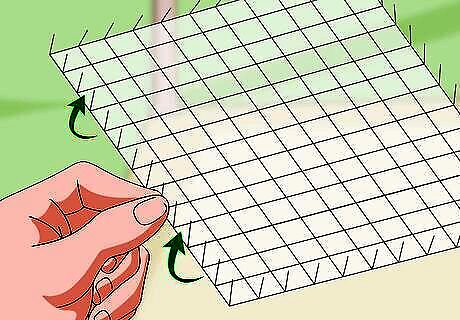

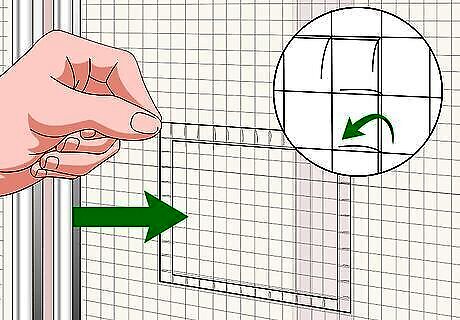

Loosen the weaving around the opening and the patch. Slack ends around the openings will help the patch adhere to the damaged screen. Bend each end on the sides of the patch at a 90-degree angle to help it lock into the screen. Keep the ends of the opening flat.

Weave the patch's ends through the screen. Work the bent ends of the patch through the open screen's weaving. When they're locked in, bend the wires of the patch flat on the other side of the screen to hold the patch in place. Some patches have an adhesive backing while others do not. If yours does not, secure the patch with a clear, waterproof silicone glue.

Comments

0 comment