views

Exposing the Strut

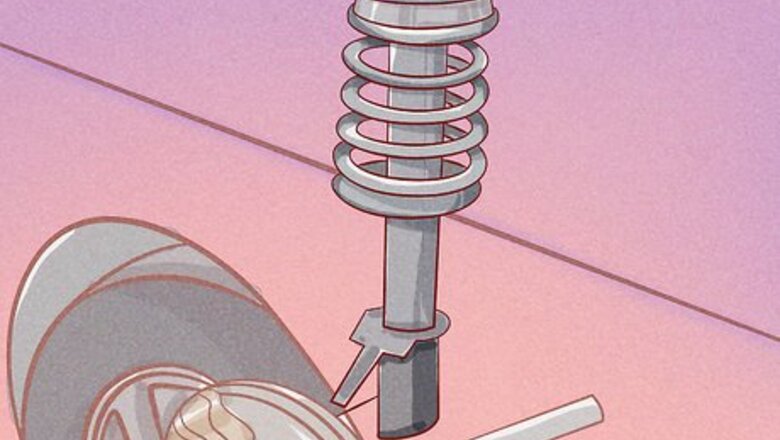

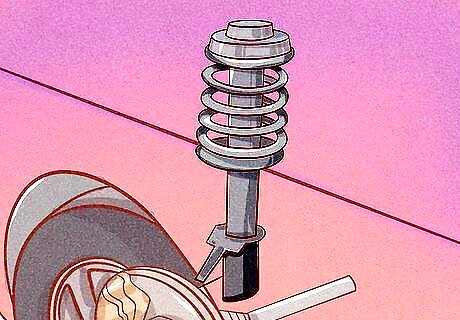

Locate the strut assembly. The struts are cylinder-shaped pistons filled with hydraulic fluid, usually shaped a bit like a metallic road cone with a spring wrapped around it. Open the hood and locate the strut bolts, usually a circle of three bolts on a pan in the engine compartment, to each side of the car, near the windshield. In the center of the ring of bolts will be the bolt for the strut pan itself. Don't loosen any of these bolts yet, especially not the center bolt, but use this to guide you to your working spot.

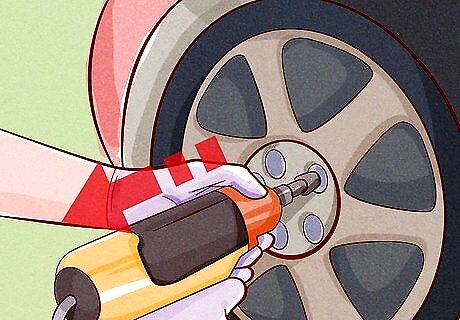

Remove the wheel. First, loosen the bolts securing the wheel with a lug wrench and lift the car with a jack, positioning the jack according to the Owner's Manual instructions for changing a tire. Once the car is raised, position a jack stand under the car for stability. Remove the bolts that secure the wheel and remove the wheel. It's always important to use jack stands to secure the car. Do not attempt to do this job only supporting the car on the jack. Jacks can shift suddenly, dropping the car and possibly trapping you under it. Car jacks use hydraulic power that can fail suddenly and need to be backed up by jack stands to do the job safely. Invest in a couple of jack stands.

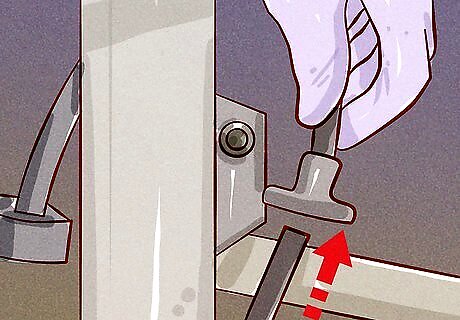

Remove the brake line support if necessary. You might need to remove the brake line support bracket from the strut assembly. This isn't a feature on all cars, so disregard this step if you don't see a small bracket holding the brake line to the strut. If you do, unscrew the bracket with the appropriate size socket wrench and move the brake line up and out of the way so you can remove the strut.

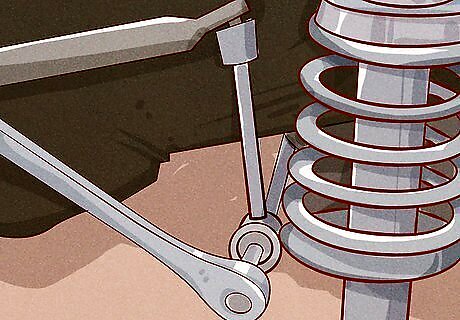

Drop the sway bar if necessary. Also called the stabilizer or the anti-roll bar, the sway bar works along with the strut assembly to stabilize the car during bumps and irregular road conditions. To do this, you need to remove the mounting bracket with a socket wrench and rotate the sway bar out of the way. Look for a small metal bracket attaching a metal bar (usually black) to the strut and remove it. Again, this won't always be an obstacle on all cars; you might just need to loosen the strut from the steering knuckle and free it. Once you've gotten these obstacles out of the way, you're ready to remove the old strut.

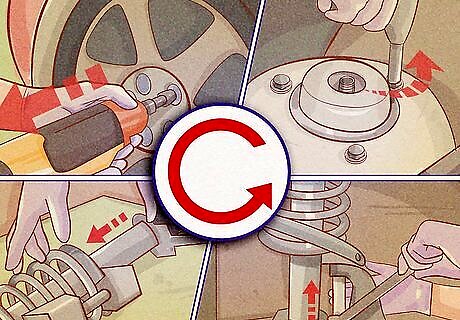

Removing the Old Strut

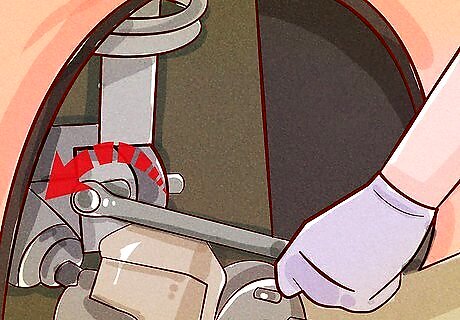

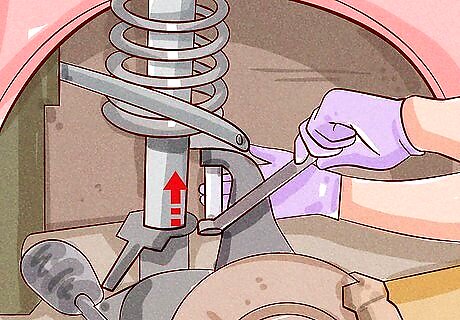

Remove the bolts from the steering knuckle. There are most likely two or three large bolts holding the strut to the steering knuckle. Remove these by removing the nuts from the assembly and loosening the strut. This is often rusted on and difficult to remove. You might choose to spray some rust loosening spray like WD-40 on equal onto the bolts before you can free them. Try hammering a few times on the knuckle itself to loosen things up a bit before hammering directly on the bolts holding the strut to the knuckle. This might take some elbow grease. Depending on the model of your car, you may also need to place your jack under the steering knuckle to raise it slightly and make the bolts visible. Once the strut bolts are out the strut and steering knuckle are separated.

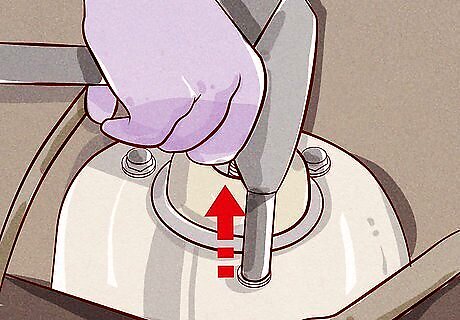

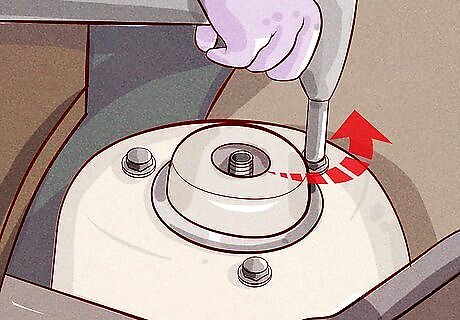

Open the hood and locate the strut towers to remove the bolts. Usually they are located at the midpoint of the inside fender well and look like cylinders. They are most likely held in by three small bolts. Remove the strut tower bolts. Do not remove the center nut or the strut will come apart and it is under high spring tension. Since you've removed the bolts from the steering knuckle, the strut might fall loose after you remove these bolts. It might help to have a partner holding onto the strut assembly while you loosen these bolts.

Pull the old strut free. Don't unscrew the center bolt on the top of the strut pan until you've compressed the springs, if you're going to. If you've got a quick-strut assembly, you can discard the old strut and skip forward to installing your new fully-assembled strut. It's recommended that the beginner forego attempts to compress the spring on the old strut using a spring compressor or spring clamps. This method is used to save money by salvaging the old spring and installing it on the new strut, but if you don't have your own strut compressor, it will run you $700. It makes more sense to spend the extra cash on a quick-strut assembly, which is pre-assembled and only requires that you install it in the car.

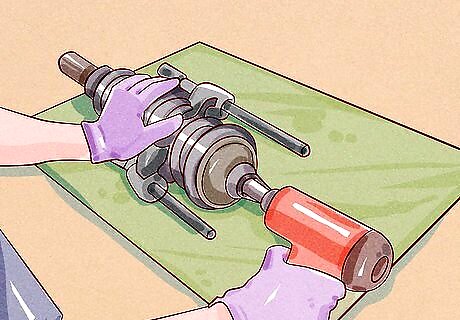

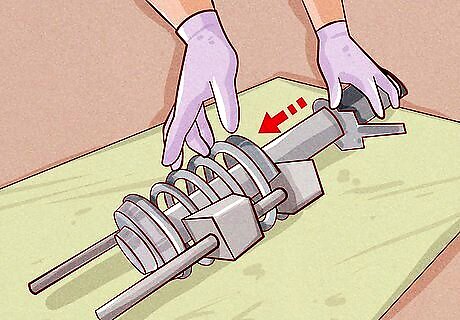

If you have access to a spring compressor, consider removing the spring. Making sure the compressor is secure and pointed away from anything that you do not want damaged, compress the spring with a spring compressor, or have someone more experienced do this. At the very top of the strut is a large nut on top of what looks like a disc, but is actually the strut bearing. Remove the large nut on top of the strut with ratchet and socket combination, and hold the strut rod with a wrench just below the strut bearing. Make a note of the strut top plate rotation before removal and reinstall in the same position. The strut can now be removed from the spring while the spring is still compressed by the spring compressor. Check the top plate bearing if it needs to be replaced.

Assemble the new strut. Put the new strut into the spring. Make sure to include any rubber parts from the old strut. Install the strut bearing over the spring and install the new strut rod nut to the manufacture specified torque while holding the strut rod to prevent spinning the strut shaft. Again, if you've purchased a quick-strut, don't worry about monkeying around with the spring on the old strut. Discard it and skip to installation.

Installing a New Strut

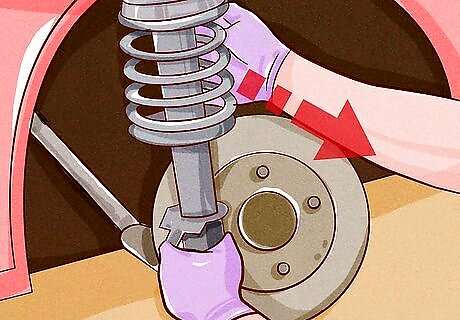

Install the completed strut assembly back into the steering knuckle. Replace the bolts, leaving them finger tight, allowing the assembly to move freely.

Place the strut assembly back into the strut tower and replace the strut tower bolts. Now you can tighten the bolts with your wrench, securing the strut assembly to the steering knuckle and torquing to the manufacturer's specifications. If you needed to move the sway bar or the brake line support, replace these at this time.

Replace the wheel. Tighten the lug bolts finger tight before lowering the car. Jack the vehicle up slightly to remove the load on the jack stands, then remove the jack stands and lower the vehicle to the ground. Tighten the wheel to the proper specifications, as well as the strut tower bolts.

Perform a final check to make sure nothing was incorrectly fitted. Test drive at low speed to evaluate the vehicle safely. Avoid high speed driving or high-traffic areas. It's possible that the vehicle may require alignment. If the vehicle pulls to either side or otherwise does not drive normally, perform alignment by measuring the degree of difference and adding cams to adjust the issue.

Repeat the process for all struts you want to change. It's cheaper to replace struts on a need-to basis, but they tend to wear out all at once, so you might as well do the rest if you're willing to invest in two or four new struts. The process will work in the same basic way for struts in all positions. Not all cars have rear struts. Check your owner's manual before buying unnecessary parts.

Comments

0 comment