views

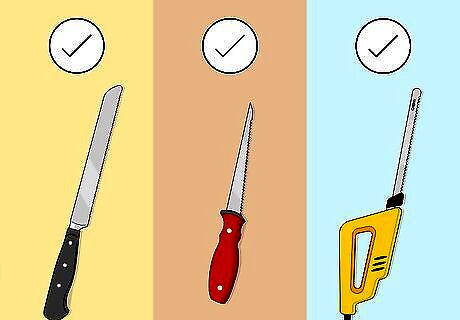

What’s the best tool to cut ROCKWOOL with?

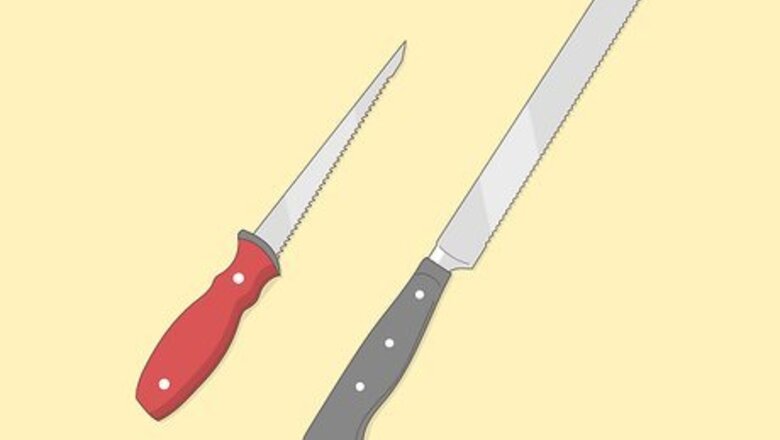

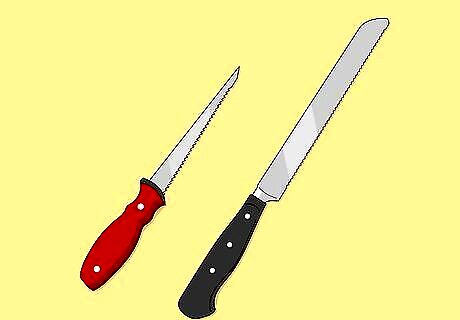

Use a serrated drywall or bread knife. ROCKWOOL boards have a soft, fibrous texture, very similar to a loaf of bread. The manufacturer recommends using a serrated blade to cut through it easily. You have a few choices on what type of blade to use. Since ROCKWOOL's texture is similar to bread, the company recommends a normal bread knife to cut the boards. A drywall knife will also make quick work of any ROCKWOOL boards. Some contractors recommend using a small handsaw to cut through the boards.

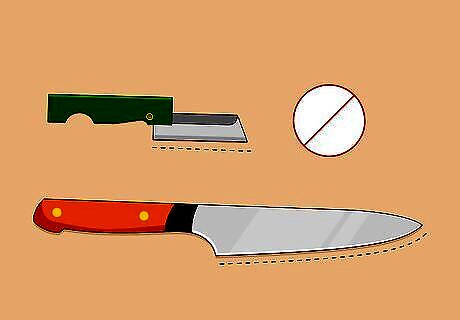

Can you use a utility knife or razor?

The manufacturer does not recommend using any straight blade. Utility knives, razors, and straight blades tend to dull quickly when cutting ROCKWOOL products. They could also tear the boards, which you definitely don’t want to happen. It’s best to skip any kind of straight blade and use either a special instillation knife designed just to cut rock wool or a serrated type of knife.

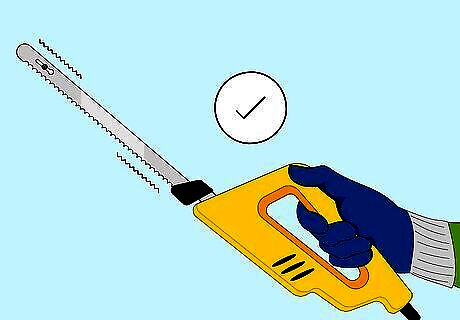

Is there a faster way to cut ROCKWOOL?

Yes, some pros use an electric cutting knife to make the job easier. Cutting the boards by hand can take a while, and rocking your arm back and forth constantly can be tiring. If you have a lot of ROCKWOOL to cut, this might get old fast. Luckily, the answer is a serrated electric knife. Instead of carving a turkey, you can make quick work of any ROCKWOOL boards. An electric knife is also easier to maneuver, so if you have to cut the boards into shapes to fit around fixtures, this is a great option. Do not use this knife to cut food without washing it thoroughly first.

Do I need different tools for different types of ROCKWOOL?

All ROCKWOOL products can be cut the same way. ROCKWOOL makes a few different types of boards, like safe’n’sound, comfortbatt, and comfortboard. Luckily, these insulation types can all be cut the exact same way, so no need to get extra tools.

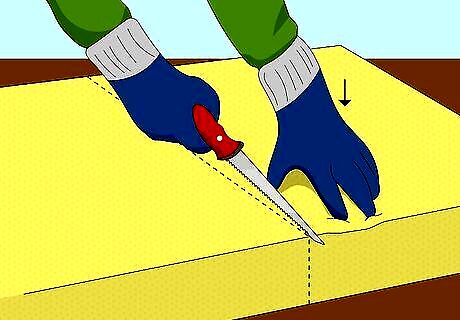

How do I hold ROCKWOOL in place while I cut it?

Just press it against the floor with one hand while you cut with the other. You don’t need any tools or equipment to keep the boards in place while you cut. Simply lay it on the floor and hold it down with one hand, then cut it with the other. If the board is moving, just press a little harder to keep it in place. If you're cutting on a floor and need to protect it, put a flat wooden board down and cut the ROCKWOOL on top of that. Make sure the ground is dry before pressing the ROCKWOOL down. It’s okay if the ROCKWOOL does get wet, but dry it out completely before you install it.

Do I need any protective equipment?

Use goggles, gloves, long sleeves, and a respirator. ROCKWOOL is made of very finely ground and spun rock. This can cause skin irritation and get in your eyes, nose, and mouth. Always wear pants and long sleeves, and protect yourself with gloves, goggles, and a mask so you don’t breathe any dust in. The manufacturer recommends wearing at least an N95 respirator to prevent dust from getting into your lungs, so a regular dust mask won’t cut it. If you can, keep the windows open while you’re cutting the ROCKWOOL too. This filters out any dust in the air.

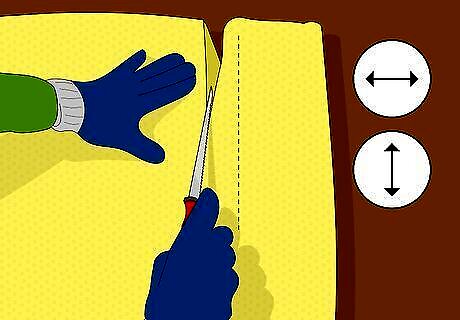

Do I have to measure the ROCKWOOL before I cut it?

Yes, you will have to do some measuring. Use a tape measure and measure the space that you’re installing the ROCKWOOL in. Then add 1 in (2.5 cm) to your measurement to make sure the board makes a snug seal, and cut the board according to those measurements. For example, if you want to install a board that’s 24 in (61 cm) across into a section that’s 18 in (46 cm), then cut 5 in (13 cm) off the board so it’s 19 in (48 cm) in total.

Can I also cut the ROCKWOOL lengthwise?

Yes, there’s no difference. ROCKWOOL cuts just as well widthwise and lengthwise. No matter which direction you need to install it, the cutting process is the same. Normally, you'll have to cut the ROCKWOOL lengthwise to fit between studs or ceiling rafters. You'll then have to cut the next board widthwise and lengthwise to fit beneath the first one.

Comments

0 comment