views

Measuring and Deactivating the Pump

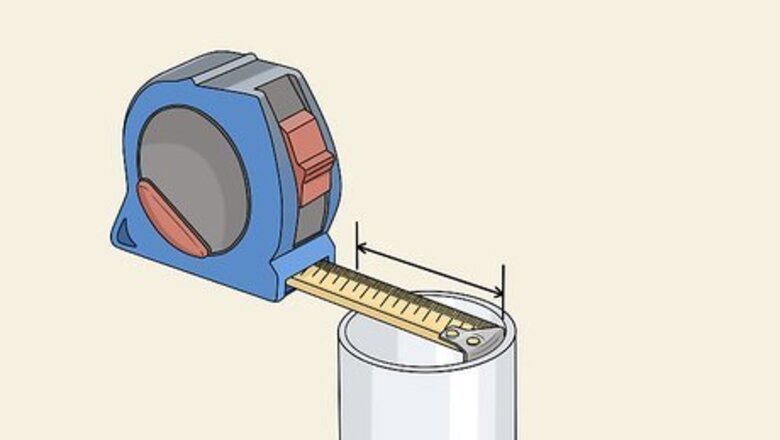

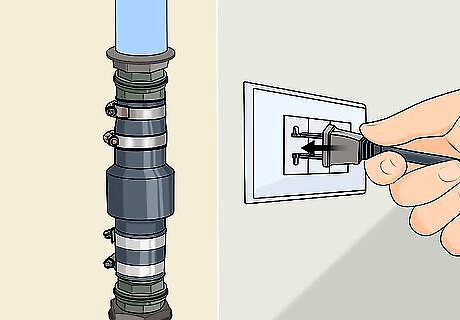

Measure the diameter of your existing drainage pipe. PVC pipe often has the diameter printed somewhere on it. If yours doesn’t, you can hold a tape measure across an open end of the pipe. Detach the old sump pump check valve if you have one in place. Otherwise, deactivate the pump and then cut through the pipe to measure across it. The size of the pipe matters a lot. The sump pump, valve, and pipe fittings have to be about the same diameter so they fit together seamlessly. If you are unable to get an accurate measurement, consider cutting out a small portion of the pipe near where it emerges from the pit containing the pump. Take it with you when you buy parts.

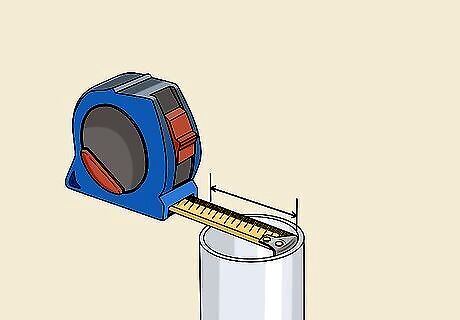

Purchase the PVC fittings you need for the installation. Sump pumps and valves make use of PVC pipes to direct water outside your home. PVC is a type of plastic pipe that is very waterproof and damage-resistant. There are different types of fittings you can use to fit any valve into an existing drainage pipe, so shop for a few that fit the pipe in your home. You will need: A pair of PVC couplings or adapters. A pair of PVC nuts. A pipe cutter or hacksaw. PVC cement and an applicator. All of these supplies are available online and at most hardware stores.

Buy a new valve that is the same diameter as the drainage pipe. Use the diameter measurement you took to pick out a valve. If you have an old valve, you can measure its length and diameter to get a more accurate estimate of what you need to shop for. Measure between the metal clamps on the valve or the PVC couplings on the drainage type to determine the valve’s length. When picking out a new valve, also note the features between different brands. Most valves are 1 ⁄4 to 1 ⁄2 in (3.2 to 3.8 cm) in diameter, so picking out one usually isn’t too tough. The length isn’t quite as important as the diameter. This is because you can always trim the drainage pipe to make the valve fit. Check valves are mostly all the same. Some of them have more plastic and require PVC couplings to fit to a pipe while others have metal clamps. Some are quieter or have an extra branch to connect to other pipes.

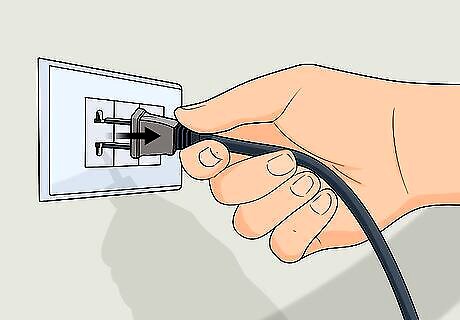

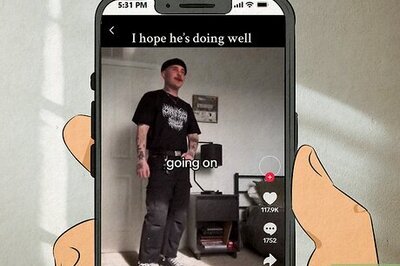

Unplug the pump’s power cord before installing the valve. Before you get started, turn off the electricity to the pump. It’s easy to do simply by unplugging the power cord from the wall outlet. Set the cord aside so it doesn’t fall back into the pit with any water that many still be in there. Wait for the pump to drain any water in its pit before deactivating it. A little bit of water may come back down the drainage pipe, but this is unavoidable unless you have a working valve installed. Note that the cap on top of the pump has electrical wiring in it. If you’re looking to take additional precautions, you can open the cap and detach the wires, but this usually isn’t necessary.

Opening the Drainage Pipe

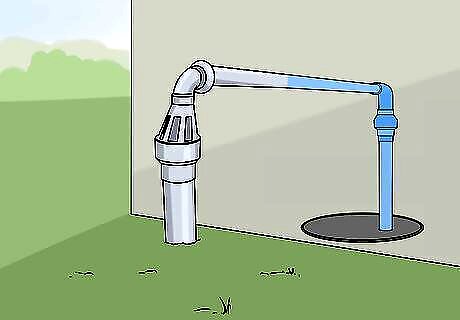

Locate the drainage pipe between the pump and the wall of your home. The drainage pipe connects to the sump pump, so look into the pit to follow it from there. To get a clearer view of the entire pipe, lift the cover off the hole containing the sump pump. The valve has to be installed on this pipe in order to prevent water from flowing back toward the pump. It is typically the only pipe leading to the sump pump, so it isn’t too tough to identify. The pipe always takes water out of your home. If there are several pipes nearby, you may wish to follow it out of your home so you don't end up cutting the wrong one.

Measure the length of the valve you plan on installing. The valve fits on the discharge pipe. If your sump pump is already installed, fitting the valve means removing a section of the pipe. Many check valves have a central section where the pump is and threaded ends that connect to the pipes. Measure the central part from one end to the other. There are a couple of different pump styles, so there are ones that have metal clamps. If you’re using one like this, measure the distance between the clamps.

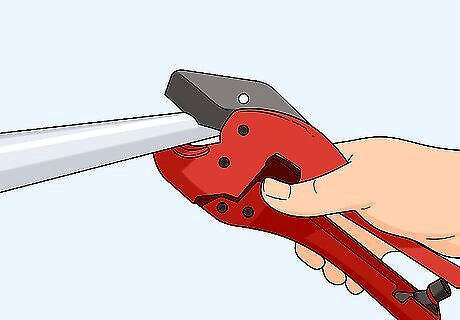

Cut the pipe if you’re installing a new valve. Try installing the check valve on the vertical length of pipe emerging from the sump pump pit, if possible. Use a PVC pipe cutter or a hacksaw to slice across the pipe twice. Remove a section of the pipe that is about the same length as the valve. Remember, you are better off cutting the pipe several times than taking out too much, so err on the side of caution. The valve is easier to install on the vertical part of the pipe, which is right near the sump pump at arm’s reach. If you can access a horizontal part of the pipe, try installing it there to compensate for gravity pulling water back down toward the pump. Cut gradually and test-fit the parts before making corrections. Leaving the pipe a little long at first is fine and safe since you can always correct it later.

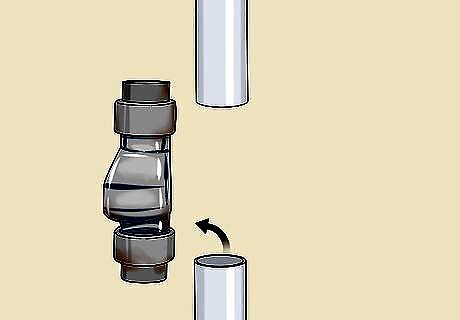

Remove the old valve if you’re replacing one. Instead of cutting the pipe, detach the old valve from the pipes. This will depend on the kind of valve you have. If yours has metal clamps securing it to the pipe, turn the screws on the clamps counterclockwise to loosen the valve. Disconnect the lower pipe first, then hold a bucket underneath it to catch any water that comes out of the valve as you finish detaching it. Some valves use PVC cement and couplers instead. Use a hairdryer to heat the pipes until they turn soft. Then, rotate the pipes counterclockwise with pliers until you are able to slip the valve off of them. Replace an old valve if it is worn out, leaky, broken, or loud.

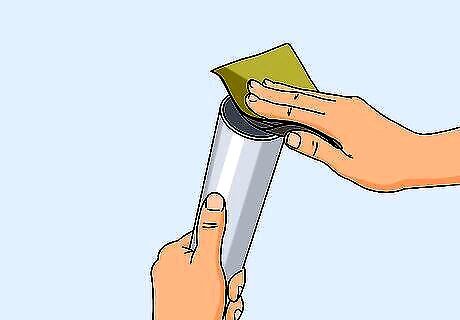

File the edges of the pipe smooth with 180-grit sandpaper. The freshly-cut PVC pipe can be very sharp, so mind your fingers. Lightly rub the sandpaper around the rim of each cut end on the remaining PVC. When the pipes feel smooth to the touch, they are ready for the valve. You can use higher-grit fine sandpaper, like 220, if you don’t specifically have 180.

Connecting the Valve

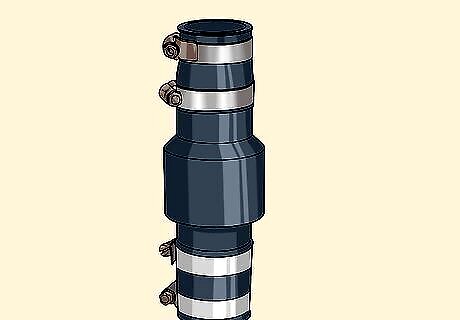

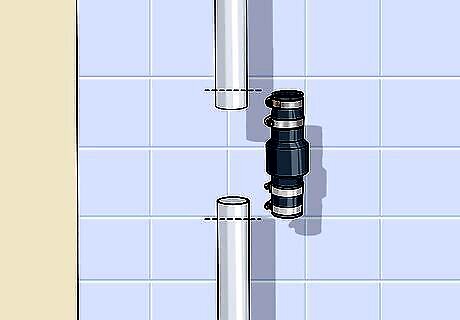

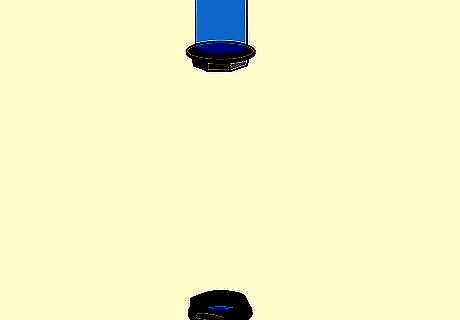

Fit PVC nuts onto each of the pipes. PVC nuts are basically rings that keep everything held together and leak-proof. They have to be fit on first before the valve is connected to the pipes. Slide one on the lower portion of the pipe and let it rest there for now. Fit another one on the upper length of pipe and hold it in place. Note that some valves have metal clamps on the ends. They function as both PVC nuts and couplers. You only have to tighten the clamp screws to secure them.

Place PVC couplers on the ends of the pipes. Couplers are small PVC tubes that join pipes and installations like check valves. Each coupler fits on the end of a pipe. Start with the upper coupler, pushing it onto the pipe. Once it is in place, let go of the PVC nut and fit the lower coupler onto the opposite length of pipe. If you’re using PVC adapters, plug the threaded ends into the existing pipes. Screw them in clockwise until they are secure.

Position the valve in the gap between the pipes. Turn the valve so the arrow printed on it points upward. The valve most likely came with a pair of rubber o-rings for waterproofing, so slide them on the ends next. Then, fit the valve in place. It’s simple, but starting with the lower end is usually a little easier. Rotate the couplers clockwise by hand to tighten the connections, then slide the PVC nuts over them. This is called a dry fit since you haven’t glued the pipes and valves. Use it to test the fits. This is the last opportunity you have to make adjustments! You may find the fit to be a little tight at first. Trim away the excess length so that all the parts fit together perfectly. EXPERT TIP David Balkan David Balkan Professional Plumber David Balkan is a Professional Plumber, CEO of Balkan Sewer and Water Main Service, and President of Balkan Sewer and Drain Cleaning. As a hands-on owner of these companies for over 40 years, David is knowledgeable about water service lines, sewers, and drain line issues. David is a Committee Chairman of the Master Plumbers Council and has sat on the Executive Committee of the Sub Surface Plumbers Association of New York for over 30 years. His knowledge and solution-oriented approach contributed to Balkan Sewer and Water Main Service being the largest and most trusted service in New York City and the recipient of the 2017 Angie’s List Super Service Award. David Balkan David Balkan Professional Plumber Add check valves to pump outflows. Put a simple check valve on the outflow discharge pipe of any sump pump. This will stop water from flowing back into the sump pit after the pump shuts off. This keeps the area pumped dry.

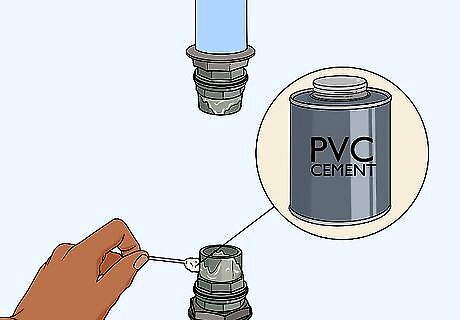

Spread PVC cement around the pipes and couplings to secure them. Unfortunately, you have to take everything apart to do this, but at least you know you will end up with a perfect fit. First, use a cotton swab to coat the outside edges of the existing pipes. Follow up with a coating of cement on the insides of the couplings. Finish by putting all the parts back together. Spread enough cement to completely cover the space where the couplings overlap the pipes. Remember to put the nuts on the pipes first so you can slide them over the couplings once you fit the valve back into place.

Let the cement dry for about 2 hours. When joining the PVC couplings, install the upper one first. Hold it in place for about 30 seconds to bond it to the pipe. Repeat this with the second one. Then, give everything plenty of time to dry before operating the pump. Be on the lookout for any open gaps in the pipes. If everything fit together, you shouldn’t see any. Correct problems before the cement has a chance to dry.

Test your sump pump check valve. With the sump pump installed, you finally get to enjoy the results of your hard work. Put the pump back in its pit first if you removed it. In order to test it, pour some water in with it. Plug the pump into a nearby outlet and listen for the sound of water rushing through the drainage pump. You should be able to hear the flap inside of the valve open as the water pressure increases. Situate the sump pump in the center of the pit. If the drainage pipe has come loose, plug it into the spout emerging from the pump’s base, gluing it with cement. Most pumps require a coupling or adapter to connect to the pipe. The sump pump works by collecting water in the pit and pushing it up the drainage pipe. If you don’t see any water remaining when the pump shuts off, then you know the valve has done its job. Note any leaks or problems like water draining back into the hole. You may need to remove the valve and redo the connections.

Comments

0 comment