views

X

Research source

Planing With a Hand Plane

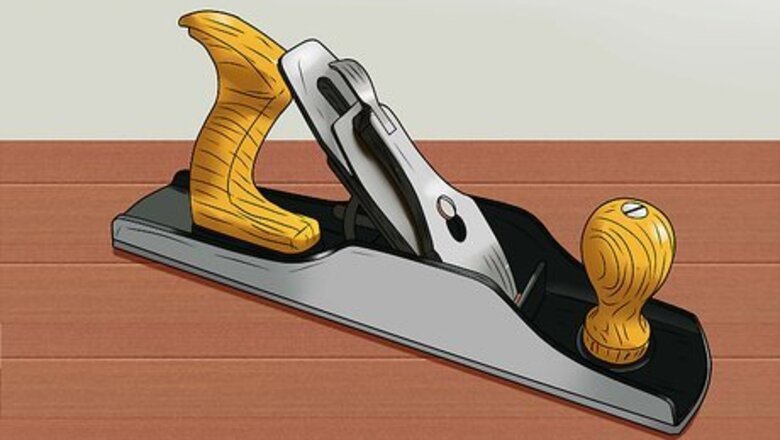

Choose the appropriate hand plane for your job. Hand planes come in several different varieties. The main defining characteristic of each type of hand plane is size. The longer the body of a plane, the more accurately it will straighten wood, as the length of the body allows the plane to bridge peaks and troughs in the wood's surface. Shorter planes, however, are often easier to control for precise detail work. Below are a few of the most common types of hand plane you'll encounter, listed from longest to shortest: A jointer plane typically has a body length of 22 inches (56 cm) or longer. These long hand planes are useful for trimming or straightening long pieces of wood, like boards or doors. A jack plane is slightly shorter than a jointer plane, with a length from 12–17 in (30–43 cm). It is more versatile than the jointer plane because of its shorter length and thus can be used to square both longboards and shorter pieces of rough lumber. A smoothing plane is about 10 inches (25 cm) long and is the most versatile of all hand planes. It can be used for general smoothing and straightening of all projects. A block plane is the smallest type of plane. This type of plane is too short to effectively straighten longboards, but is ideal for shaving very thin pieces from a surface or working in a tight corner.

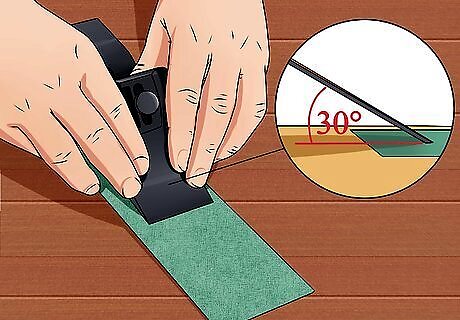

Sharpen the blade of the plane. The blade (also called the iron) of the plane needs to be razor-sharp before use - even new planes should be sharpened. To sharpen the blade, first place a piece of 220-grit wet/dry sandpaper on a flat surface. Hold the blade at a 25 or 30-degree angle so that the bevel is flat against the sandpaper. Maintaining this angle, rub the blade around the sandpaper in a circle while applying downward pressure. When a burr (an accumulation of metal shavings) forms along its back, the blade is ready to use. Remove the burr by wiping the back of the blade flat across the sandpaper.

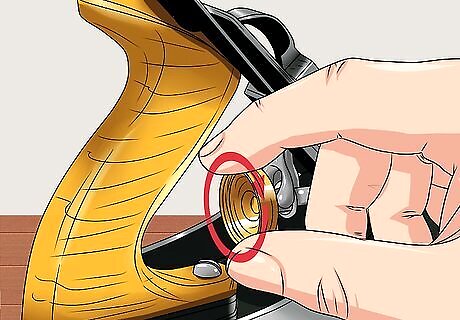

Adjust the angle of the blade. When it comes to planing wood, the angle of the blade dictates how "thick" the shavings you'll take from the surface of the wood will be. If the blade angle is too deep, you can end up jamming the plane or tearing your wood. To adjust the blade angle, turn the depth adjustment wheel, which is the small wheel just behind the blade assembly. Adjust the blade's angle until the tip of the blade protrudes just below the sole of the plane. It's good policy to start by using a shallow angle, then increasing the depth of the cut if necessary.

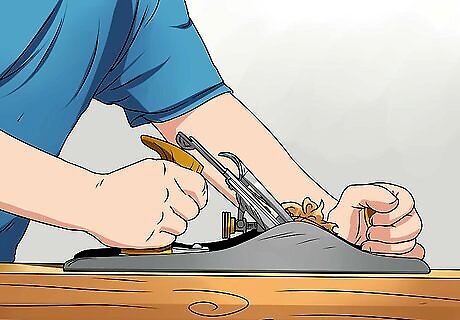

Plane the surface of the wood. Begin smoothing and flattening your wood by placing the plane at the edge of the surface. As you apply downward pressure on the front knob and press forward with the back handle, push the plane across the surface in a smooth, continuous motion. Work across the surface of your wood methodically, making sure to pay extra attention to any high spots or uneven spots on the surface of the wood. A level or straight edge can help you find uneven spots in your wood.

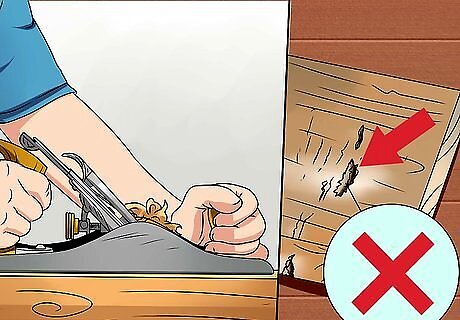

Avoid tear-out by cutting along the grain of the wood. To smooth the surface of the board, you may find that you need to plane in multiple directions. However, always avoid planing directly against the grain. Doing so can cause the blade to "catch" under minute, angled imperfections in the surface of the wood. When this happens, the plane can tear small, rough chunks from the wood's surface, rather than shaving the surface uniformly. This is called "tear-out". To fix tear-out, try re-planing the jagged spot along the grain of the wood or sanding it smooth.

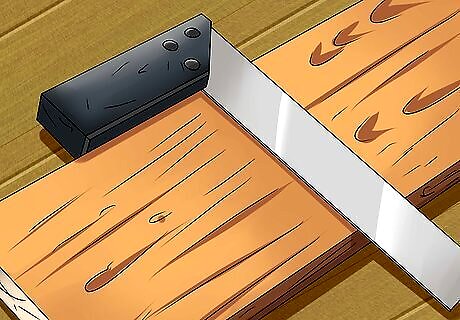

Check the accuracy of your planing. Ideally, after you plane your wood, you'll have a smooth, flat surface that sits flush with any adjacent pieces of wood. Check your wood's flatness and smoothness by laying a straight edge along its surface. The straight edge should sit flush against the face of the wood regardless of its position. If, in any position, your straight edge sits on the wood in a way that leaves gaps underneath it, you'll know that the section of the wood your straight edge is making contact with is a high spot. A try square can be used to check the angle between two adjacent faces of the wood to ensure they sit at a perfect 90-degree angle.

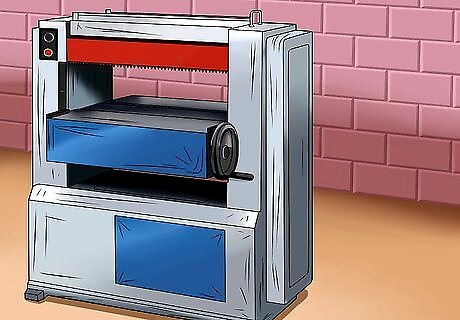

Planing with a Mechanical Surface Planer

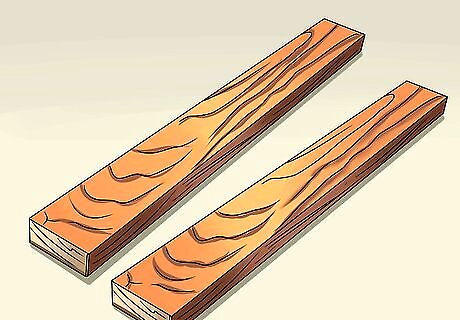

Note that surface planers generally require pieces of wood with one flat surface. Surface planers are mechanical tools that use rollers and an adjustable set of spinning blades to plane a piece of wood to a uniform thickness automatically. Surface planers are a great time-saving tool for experienced woodworkers, but it's important to know that many surface planers only plane the surface of a piece of wood relative to the opposite surface. In other words, if the bottom of the wood isn't perfectly flat, the planer will maintain this imperfection on the top surface. Because of this, you'll want to use your planer for smoothing wood surfaces only if the flatness of the opposite surface is assured.

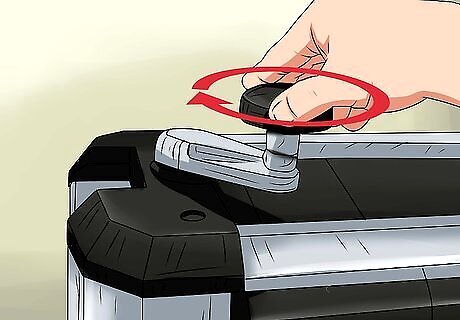

Set the planer to your desired thickness. All surface planers will somehow allow you to adjust how "deep" the wood will be planed. Often, this is via a hand-operated crank that lifts the planer's housing - the higher the housing, the shallower the planer will cut. As with a hand planer, it's wise to initially make shallow cuts. You can always cut more deeply, but you can't "undue" what you've already cut. Often, the "depth" of the cut itself isn't displayed on the planer, but the actual thickness that the wood is being planed to. Thus, to plane a 2 inches (5.1 cm) thick piece of wood by ⁄16 in (0.16 cm), you would set the planer to 1 ⁄16 in (4.9 cm) and so on. Note that most planers shouldn't be set to plane off more than ⁄16–⁄8 in (0.16–0.32 cm) at a time - doing so is hard on both the wood and the planer.

Optionally, set the depth stop. Many planers offer the capability to "lock" the planer from cutting beneath a certain depth via a mechanism called a depth stop. For instance, if the depth stop is set to 1 inch (2.5 cm), the planer will not be able to plane the wood to a thickness of less than 1 inch (2.5 cm). This is a useful feature to have if you're worried about accidentally over-planing. If you don't want to use the depth stop, set it to a very low level - one much lower than the thickness of your board - so that you'll never hit this lower limit.

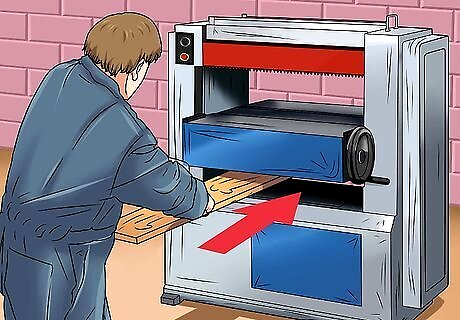

Turn the planer on and pass your wood through. When your planer is running, carefully feed the wood into the planer in a straight, controlled motion. After the wood is caught by the rollers, it should begin to feed through on its own. Keep in mind that, as with a hand plane, you'll want your planer to cut along the grain of your wood to prevent tear-out. Repeat the planing process as needed until your wood is a desired level of thickness. You can track your wood's process by scribbling lightly on the surface to be planed with a pencil before planing. As your planer removes high spots in the wood, you'll see the lines of your pencil begin to disappear.

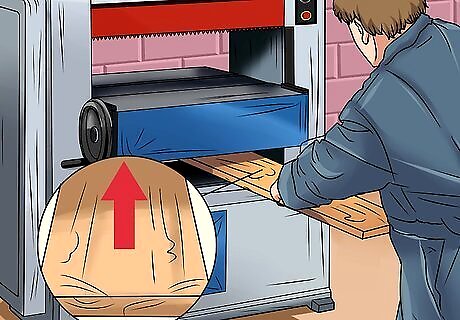

Pull up on the wood as it passes the rollers to avoid snipe. "Snipe" is a condition that surface planers can sometimes produce on a piece of wood. Essentially, the planer's rollers pull upward on the wood, causing slightly deeper cuts at the edges of the wood than in the middle. To counteract this, pull up on the end of your wood as it passes through both the front and back rollers of the planer. In other words, pull up on the "back" end of your wood as you feed it into the machine, then pull up on the "front" end of the wood as it passes out of the machine.

Use ear, eye, and/or mouth protection as needed. Usually, mechanical planers are very loud. Prevent damage to your ears by wearing appropriate ear protection, like earplugs or earmuffs. Additionally, planers produce lots of airborne dust, so if you don't have equipment in place to vacuum up the dust as it's being created (like a dust collector), you'll want to use eye protection and a surgical mask to protect yourself.

Comments

0 comment