views

Understanding Your Deep Well Pump

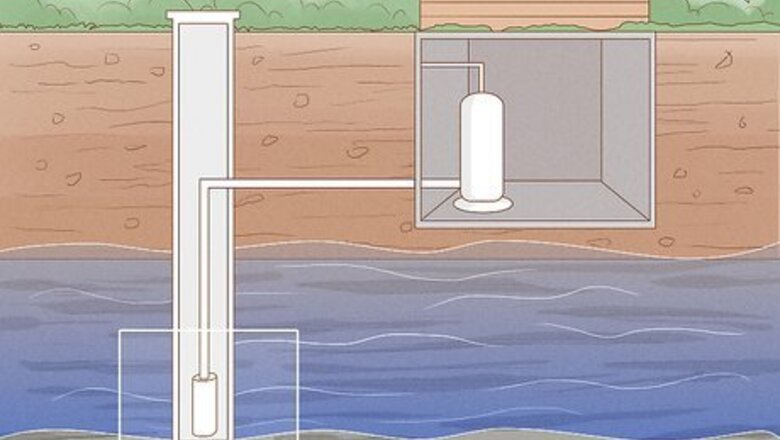

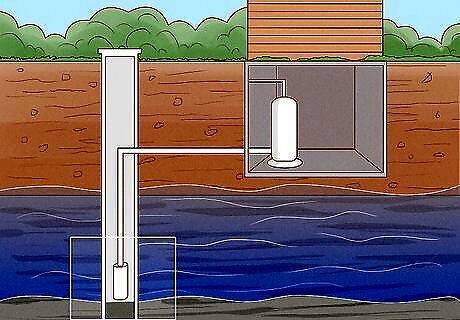

What is a deep well submersible pump? A submersible pump is a water pump that has to be submerged underwater to work. A deep well submersible pump is one that’s deep underwater, meaning the water has longer to travel. Usually, deep well pumps are situated so low because the water table is low. Although they are sometimes conflated, sump pumps are different from deep well submersible pumps. Sump pumps collect water from the sump basin, usually in the basement of a home.

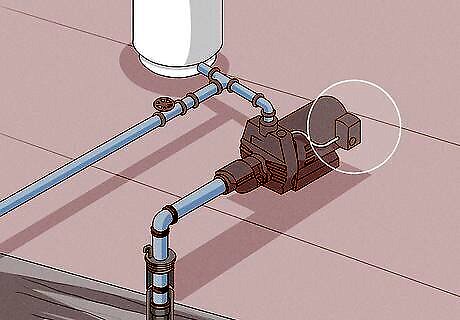

Why has my pump stopped working? There are a number of reasons why your submersible pump might have stopped working, so it’s important to count out the easy fixes first. Check the wall switch to make sure it hasn’t been turned off first, then check the breaker to see if it’s been flipped. If neither of those things work, check the pressure switch on the pump itself. If the breaker or the pressure switch is the problem, you may have to call in a professional.

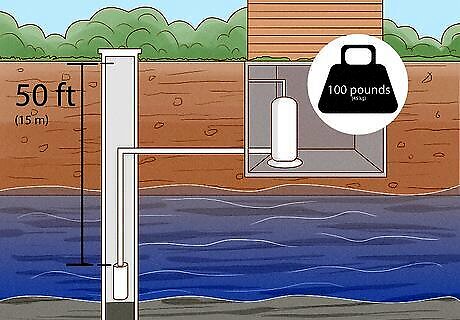

How deep and heavy is my pump? Usually, submersible well pumps sit between 50 and 300 feet (15 and 91 m) below the ground. If your well is 100 feet (30 m) deep, the pump usually weighs around 100 pounds (45 kg). Deeper wells can have pumps that weigh up to 300 pounds (140 kg). If your pump is too heavy to lift by hand, you’ll need a truck with a crane to help you out. If you aren’t sure how deep your well is, get your property records from your local building department. You can absolutely pull your pump out by yourself; however, it is tough work, and you can damage the pump in the process. If you’re at all nervous about the prospect of pulling up your pump or you don’t have the right equipment for it, call a professional.

Pulling a Deep Well Pump by Hand

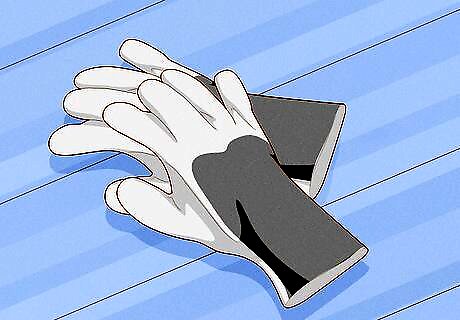

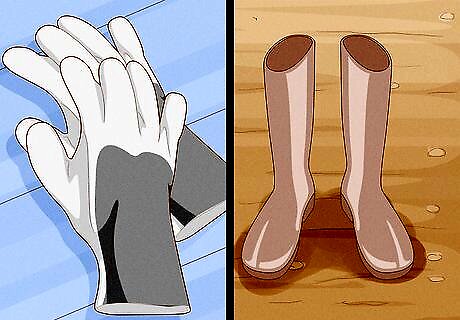

Safety first: Always shut off the breaker to the pump before you start. Then, clear a 10 feet (3.0 m) radius around the opening of the well to make sure you don’t get caught in any vegetation or debris. Put on some non-slip gloves and safety glasses to protect yourself throughout the process. It is very important to turn off the breaker before you start messing with the pump. If you don’t, you could seriously injure yourself.

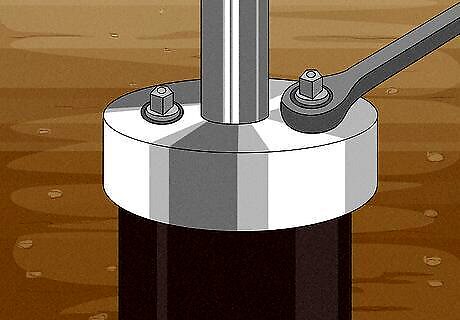

Pry the well cap off the casing. To open up the pump area, use a ⁄4 in (1.9 cm) socket and ratchet to take off the nuts on top of the casing. Then, slide a flathead screwdriver underneath the cap to slowly pry it off of the casing and open it up. You might meet some resistance here, especially if you haven’t opened up your well cap in a while (or ever).

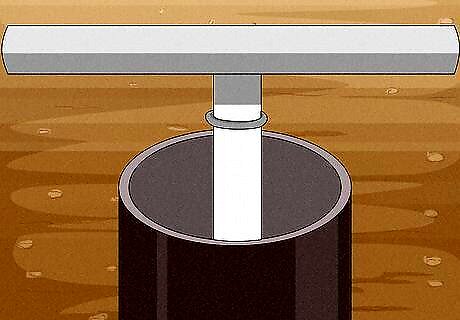

Thread a T-handle pump removal tool into the pipe. Shine a flashlight into the well and look for the pipe with a T-fitting. Slide the end of the T-handle pump tool into the well and turn it clockwise into the pipe to thread it in. Make sure it’s secure before you move on, since this is what you’ll be using to pull up your pump. If you’re having trouble interesting the T-handle tool (which is common, since the pipe may be corroded), try lining it up as best you can and then gently tapping on the top of the tool with a hammer. The slight pressure can help guide the tool onto the pipe to make for an easier job.

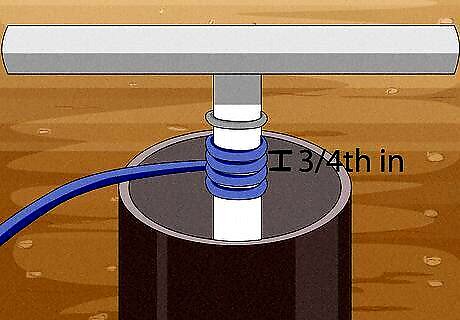

Tie a safety rope to the water pipe below the T-handle tool. This step is really important, since a safety rope is all that stands between you and accidentally dropping your pump into the abyss. Grab a rope that’s at least ⁄4 inch (1.9 cm) thick and tie it in a tight knot around the water pipe itself, just below the T-handle tool connection. Leave the rope sticking out of the well cap so you can easily grab it if you need to. If you do drop the pump once you disconnect it from the well line, it will take a whole lot of time and money to get it back.

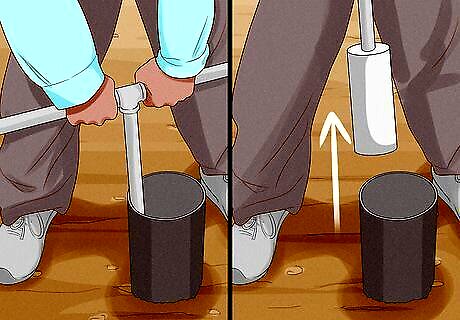

Pull the pump up and out of the casing. Here comes the sweaty part of the job. Have one person pull on the T-handle tool while another person holds the safety rope. Start walking backwards as you pull to remove the pipe and the pump at the bottom. This can take a long time, and it takes a lot of work. Feel free to switch out with your friend so you can take turns pulling the pump. Focus on keeping the pipe untwisted as you pull upwards so you don’t rip or tear it. Once you have the pump completely out of the ground, you can take a look at the mechanism itself and diagnose it.

Pulling a Deep Well Pump by Machine

Safety first: Shut off the breaker to the pump before you start working. Put on non-slip gloves, work boots, thick pants, and safety glasses, then clear a 10 feet (3.0 m) radius around your work area to stay safe. Remove any large rocks or shrubbery that might get in your way. Make sure the machine or vehicle you’re using has a clear pathway to get to the well cap and back.

Open up the well cap with a screwdriver. Use a wrench to loosen the nuts and the bolts on the well cap, then take them off completely. Slide a screwdriver in between the cap and the well, then pry it open gently and set the cap aside. You’ll need the well cap later when you put your pump back, so don’t lose track of it.

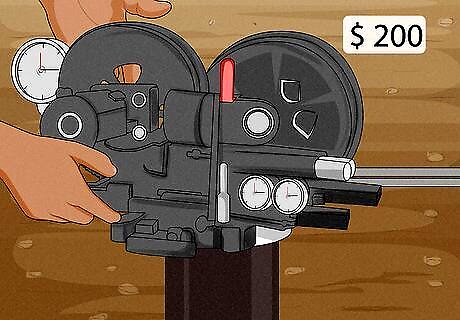

Remove the top part of the pump pull machine. Pump pull machines are hydraulic machines that work by grabbing the top of the pump pipe and pulling it upwards. Once you have your machine out and ready, remove the top part that attaches to the top of the pipe and set it on top of the well cap opening. Leave the rest of the machine nearby so you can hook it up in just a moment. You can rent pump pull machines at most hardware stores, or you can buy one for around $200. There are also pulley system pull pump machines, which are slightly less expensive but don’t have the pulling power of a hydraulic machine.

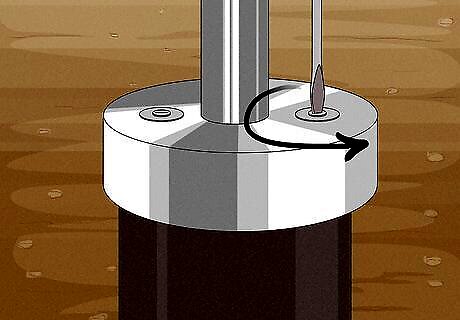

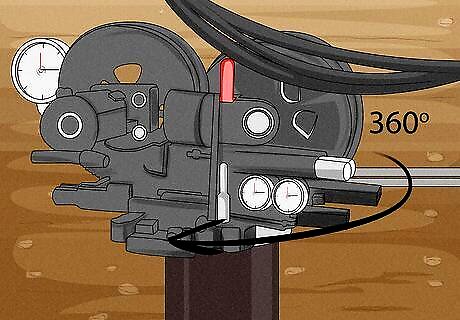

Thread the machine into the top of the pipe. With the top of the machine sitting on top of the well cap opening, thread it 360 degrees in a clockwise motion to attach it to the top of the water pipe. If you need some guidance, shine a flashlight down into the well as you do this so you can see a little better. Some machines may allow you to turn both clockwise and counterclockwise to thread them into the pipe, especially if they’re newer models. If you’re using a pulley system, hook the winch to the top of the water pipe.

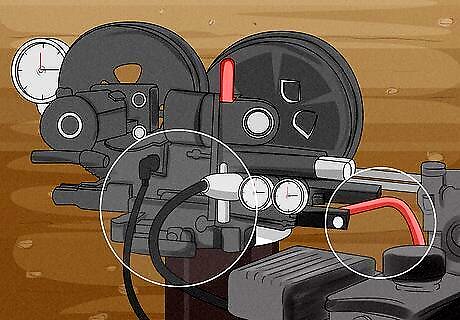

Attach the hydraulic connections. If you’re using a hydraulic machine, grab the nozzles that connect to the base and attach them to the top of the machine by twisting them in. Usually, there will be 2 to 3 hoses that connect to the base for an easy hookup. If you’re using a pulley system, you’ll have to attach the line to another surface that’s about 2 feet (0.61 m) away from the well cap, like a tow hitch or a sturdy branch.

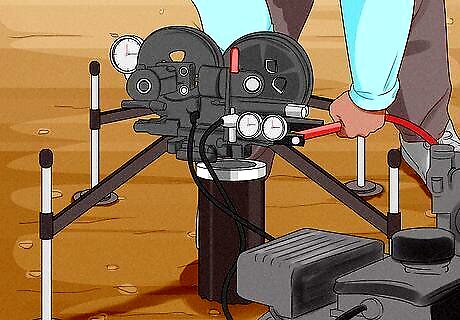

Turn the machine on to pull the pump. Flick the machine to the “on” position and watch the rubber wheels turn! As the water pipe comes out of the well, grab it and walk it backwards or in a circle to make sure it doesn’t get tangled. Once the actual pump itself comes out of the ground, you can turn the machine off. This will go much faster than pulling by hand, but it could still take up to 15 minutes. If you’re using a pulley system, you will have to detach and reattach the winch to another part of the water pipe every time the pulley runs out of slack. Keep doing this over and over until the pump comes out of the ground.

Comments

0 comment