views

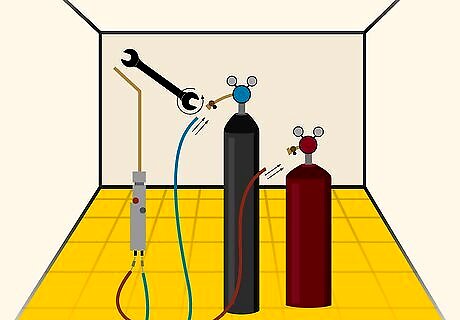

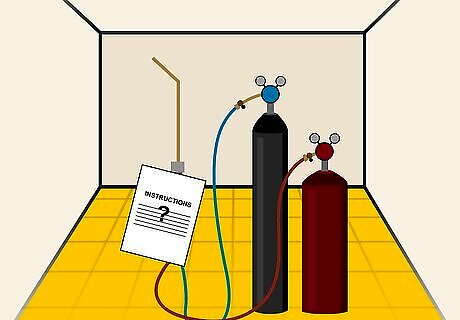

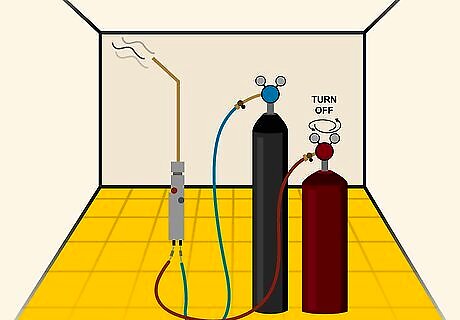

Attaching Pressure-Reducing Regulators

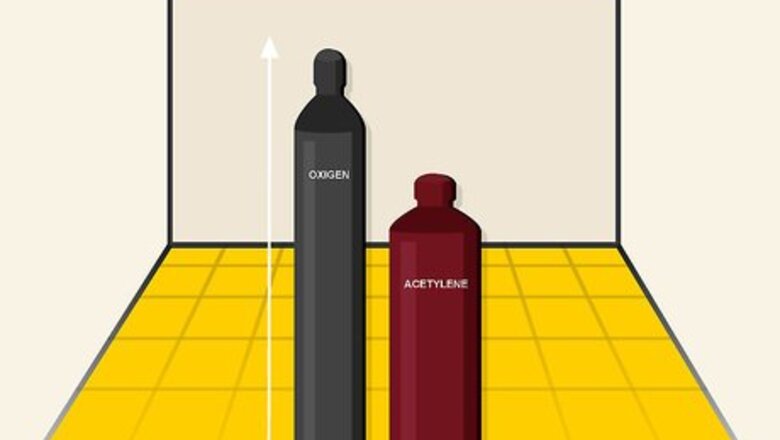

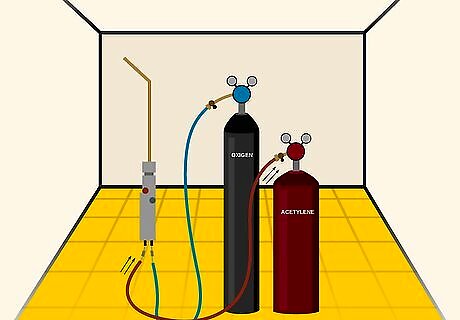

Fasten oxygen and acetylene cylinders in an upright position. If you have a cylinder cart, place both the oxygen and acetylene cylinders into it. If not, they should be securely fastened with a chain to a workbench, a wall, or a post. Cylinders should not be able to be knocked or pulled over. Cylinders should only be used and stored in the vertical position.

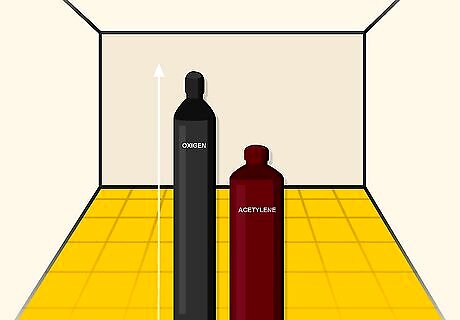

Clean the valve outlet of accumulated dust or dirt. Stand so the outlet is facing away from your body and open the valve a 1/4 turn, very quickly, and then close it. This will clear out any dust or dirt that may have settled in the valve. It needs to be cleaned out otherwise the debris might get into other parts of the torch and cause it to malfunction. Warning: never clear a fuel gas cylinder near other welding work that is in progress or near sparks or flames.

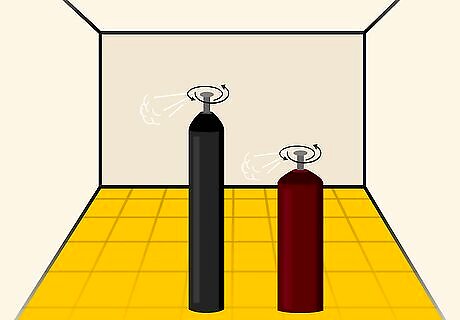

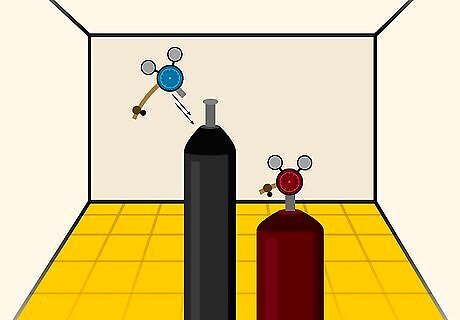

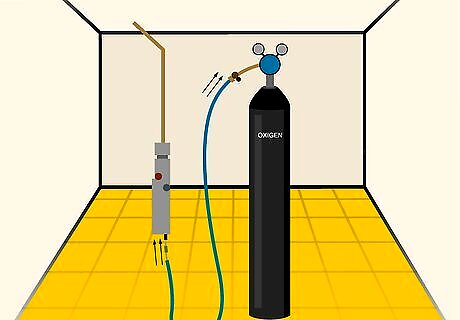

Connect the oxygen and acetylene regulators to their cylinders. The regulators let you see how much pressure you’re using while working and are essential to safely starting and operating an oxy acetylene torch. If the regulator and cylinder have different threads (meaning they don’t fit into each other), you will need to use an adaptor, which can be purchased at any local hardware store.

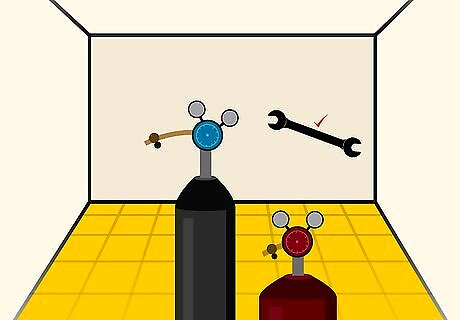

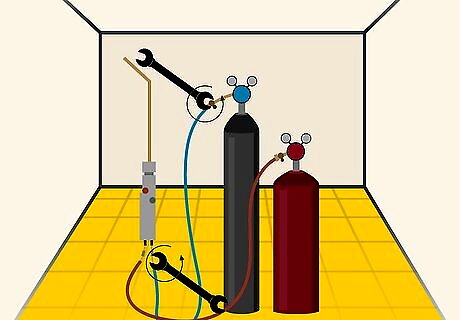

Tighten the nuts of the regulator connections with a wrench. Don’t assume because you have turned the nut as far as you can with your hand that it is tight enough. Use a wrench with a fixed opening (rather than an adjustable wrench) that is designed specifically for welding tools. You can buy these from a hardware store or a specific apparatus supplier. If you ever need to make an adjustment after the cylinder has been opened and used, make sure to close the cylinder valve before tightening the nut again.

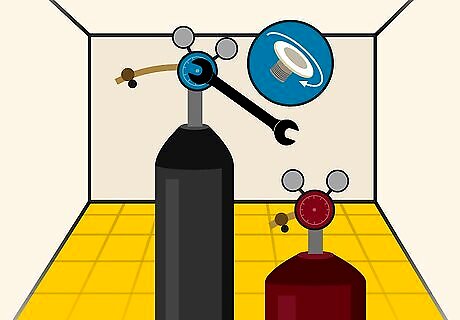

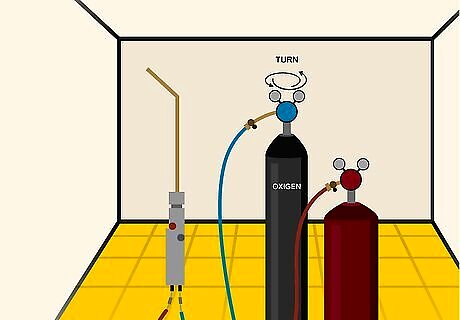

Rotate the pressure-adjusting screw to the left until it turns freely. Do this for each regulator. The valve in the regulator needs to be closed before cylinder pressure is admitted. Turning the pressure-adjusting screw counter-clockwise removes the pressure from the spring in the regulator. When the screw turns freely, you should be able to just tap it with your finger and see it move, rather than having to apply pressure.

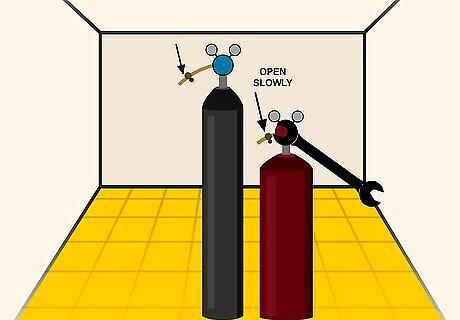

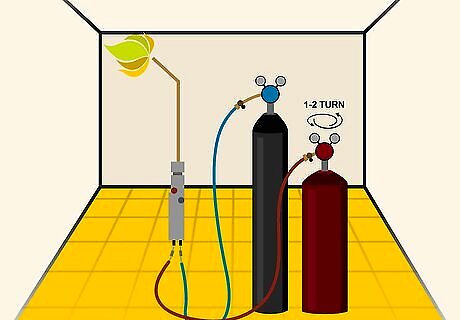

Open the oxygen and the acetylene valves very slowly. Make sure you can see the cylinder-pressure gauges, but don’t stand directly in front of the valves. Open the valves slowly to protect yourself and your machine from any potential combustion. Open the oxygen valve very slightly at first and pause until the pressure gauge hand isn’t moving any more before moving on to open the valve fully. The acetylene valve should never be opened more than 1 and 1/2 turns.

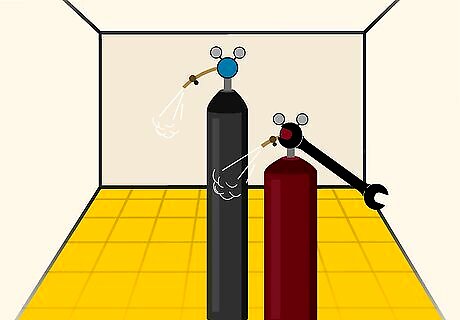

Leave the wrench on the acetylene valve while it is open. Basically, if you have an emergency you won’t have to waste time looking for an appropriate wrench. If it’s on there, you’ll be able to close the cylinder valve right away. In general, it’s smart to work in an area where you can reach all your tools without having to search for them. Think ahead when you are starting a project and bring your tools to your workspace before beginning. Review safety steps before using a torch. "I hadn't done any welding with my oxy-acetylene torch in years. When I needed to use it for a project, I realized I'd forgotten all the right safety steps. This article was a lifesaver, walking through attaching the regulators, testing for leaks, and lighting the flame properly — all stuff I used to know but blanked on after so long. Now, I can weld confidently again without worries, thanks to the refresher." - Paul C. Learn new welding techniques. "I've only ever used my torch for cutting metal before. But I've got some DIY welding jobs piling up and wanted to save money instead of hiring someone. This article explained adjusting the pressures and flame for welding so clearly. I never realized how different it is from cutting. The instructions gave me the confidence to weld simple pipes on my own for the first time." - Chris B. Revisit basics for safety. "Even as an experienced welder, it's easy to get casual with safety after years in the job. This was a great refresher on steps I'd gotten rusty on, like properly attaching hoses, checking for leaks, and lighting the flame right. Going back to the fundamentals ensures I don't get sloppy — it keeps me and others safe." - Kevin A. Get back up to speed after a hiatus. "After ten years away from gas welding, I was really nervous to use a torch again for a volunteer project. But this article quickly got me back in the groove. Reviewing gauge pressures, leak checks, and lighting techniques made me feel prepared instead of anxious. It was just the thorough refresher I needed after such a long break!" - Richard E. Have a story our readers should hear? Share it with 1 billion+ annual wikiHow users. Tell us your story here.

Connecting Gas Supplies to the Torch

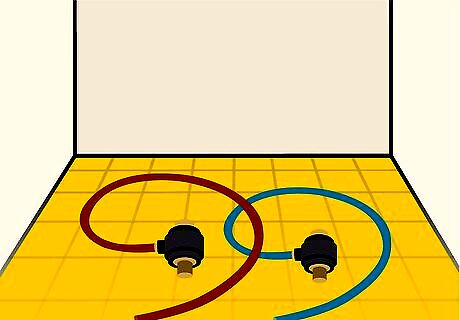

Use a hose and hose connections specific to welding and cutting. Oxygen hoses will have a green cover, while acetylene hoses will have a red cover. Never interchange these hoses as they are meant for different substances. If one of your hoses have broken, replace it—don’t use tape of any sort to try and patch the hole. A hose with a natural rubber liner is okay for acetylene service.

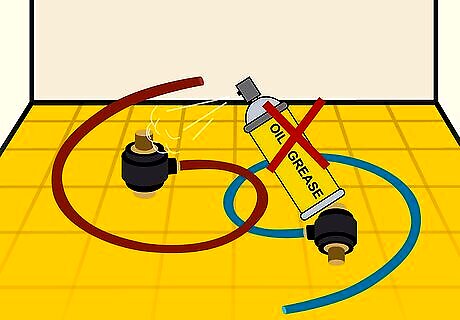

Do not use any oil or grease on the hoses. All the connections from the gas supplies to the torch are metal-to-metal, and they don’t require lubricants or sealants. Similarly, don’t use any pipe-fitting tools to connect the hoses to the torch. Don’t force connections—if the threads don’t run together easily by hand, either the threads are damaged or the parts aren’t meant to go together.

Attach the oxygen hose to the oxygen regulator and to the torch. The torch should have identifying marks on the body or the handle showing where the hose should be connected. Most torches have 2 oxygen connections because 1 is used for the cutting jet and 1 is used for the preheat flames. If there isn’t an adaptor on the torch that unites these 2 connections, you will need to use 2 oxygen hoses, 2 regulators, and 2 oxygen tanks. Most new oxy acetylene torches come with built in adapters, but double-check with the manufacturer’s instructions to be safe.

Connect the acetylene hose to the acetylene regulator and to the torch. Sometimes the torch doesn’t specify which connection is for the acetylene, though the oxygen will be clearly marked. Whichever connection is not for the oxygen is for the acetylene. Double check your connections before moving on to make sure everything is hooked up to the right place.

Tighten the hose connections with a wrench. Don’t trust your hand strength to tighten these connections for you. Use a non-adjustable wrench to securely fasten both the oxygen and acetylene hoses to the torch. Having tight connections is extremely important because they will keep both the oxygen and acetylene from leaking.

Testing Connections for Leaks

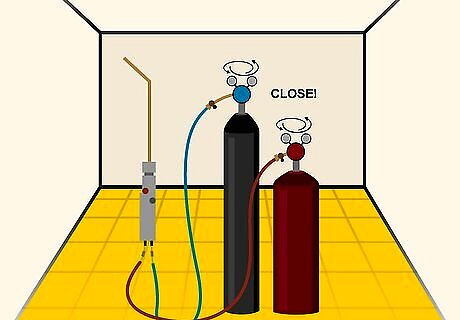

Close both torch valves. For the oxygen, turn the pressure-adjusting screw on the regulator until the gauge reads about 25 psi. For the acetylene, turn the pressure-adjusting screw on the regulator until the gauge reads about 10 psi. It is very important to test for leaks before starting your project. Leaks can cause harm to you or your surroundings and may lead to spontaneous combustion of the cylinders.

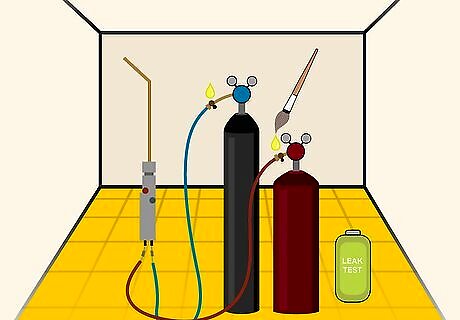

Apply a leak-test solution with a brush. Apply the solution to the cylinder valves, the cylinder and regulator connections, and all the hose connections. You can either buy a solution from the store for this specific purpose, or you can dissolve Ivory soap in water to make a thin paste for the same results. Any work brush you have on hand will do; just make sure it hasn’t been compromised by oil or gas.

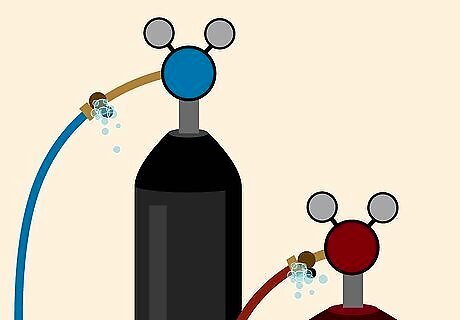

Check the leak-test solution for bubbles. Bubbles indicate that either oxygen or acetylene is coming through the connectors and the connection needs to be tightened or reattached completely. The bubbles won’t be big, like in a pot of boiling water; rather, they will be small and will make the surface of the testing solution look uneven. Give the solution 1-2 minutes to sit before checking for leaks.

Release all pressure from any system that has a leak. Reattach or retighten as needed, and apply the leak-test solution a 2nd time to test the torch for leaks again. After completing the testing, make sure to turn off both the oxygen and acetylene. If after you’ve tested and refastened any leaking areas you are still seeing bubbles, that may indicate you have a leaky hose and need to get a new one before moving on with your project.

Obtaining the Correct Operating Pressure

Turn the oxygen regulator pressure-adjusting screw. Slowly do this until you reach the desired pressure. The pressure will be indicated on the delivery-pressure gauge. Then you will close the torch oxygen valve. If you are using a cutting torch, open only the torch cutting oxygen valve. If you are using a cutting attachment, open the oxygen valve on the torch handle and the cutting oxygen valve on the attachment. Don’t set the pressure higher than what the equipment manufacturer recommends.

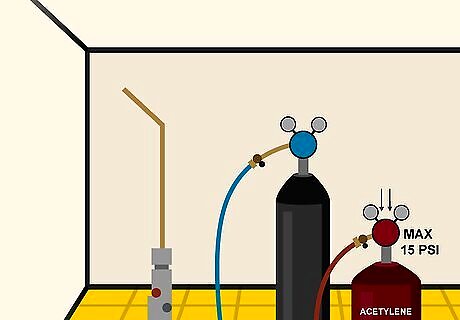

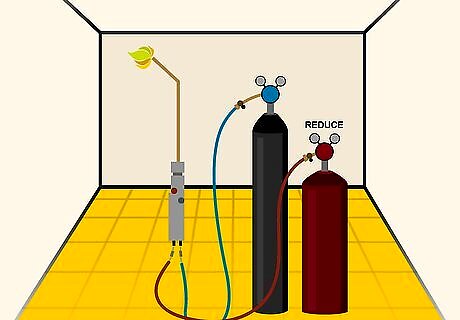

Adjust the acetylene adjuster screw to the desired working pressure. Do not exceed 15 psi. Close the acetylene valve immediately after you obtain the right pressure. You shouldn’t open the valve more than 1 full turn. If you open the valve too fast or too far, you may cause the canister to combust.

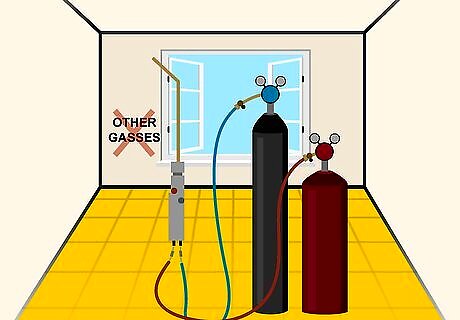

Do not release acetylene or other gasses near sources of ignition. Also, make sure you are working in a well-ventilated area. It is advisable to keep a fire extinguisher in your workspace in case there are any explosions or emergencies. Heating, welding, and cutting cause smoke and fumes that are bad to breathe in and that can irritate the skin.

Lighting the Flame

Check the manufacturer’s instructions for the torch before beginning. Though most torches follow the same operating procedure, the manufacturer’s instructions may have helpful tips or warnings that are specific to your torch. Read it thoroughly before following steps or tips from any other sources. You can also search the manufacturer online to check out more information regarding your tool. A lot of sites have community forums where people post tips and stories about their experiences that you can learn from.

Open the torch acetylene valve 1/2 turn and light the flame. Use a friction lighter rather than a match for this step. A friction lighter is also called a torch striker, and these can be found at hardware stores. You will see a flame coming out of your torch. If for some reason there isn’t a flame, turn off the acetylene valve and check your connections. Remember to not have the oxygen gas flowing when you go to light the torch.

Reduce the acetylene flow by adjusting the torch acetylene valve. The flame should start to produce black smoke around the edges. Once the black smoke appears, start to increase the acetylene flow back up again just enough to get rid of the black smoke. The flame should still be attached to the tip (it shouldn’t appear as though it has “jumped away” from it). The lighting procedure should result in a neutral flame, which is blue in color and which does not make a hissing sound.

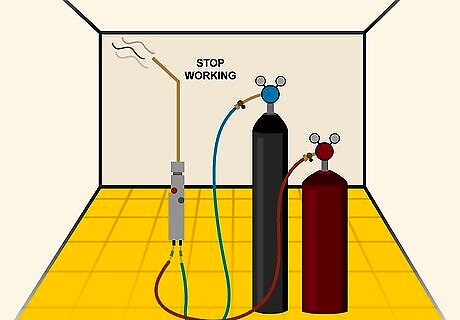

Stop working if the flame suddenly goes out. This is called “backfire” and can happen it the torch comes into direct contact with the metal. If this happens, go ahead and relight the torch again right away. If backfire occurs repeatedly without contact with the work, it may be due to incorrect operating pressures or a loose nozzle in the torch. In this case, check the operating pressures and take a look at the torch to make sure everything is connected properly. If in doubt, turn off the gasses and check your machine over before proceeding.

Turn off the torch if there is flashback. Flashback is when there is a pronounced hissing or squealing noise. This means there is something wrong with the torch or with the set up. After turning off the torch and investigating the cause, wait until the torch has cooled before attempting to light it again. If your torch keeps experiencing flashback, there may be a damaged piece that needs to be returned or replaced.

Comments

0 comment