views

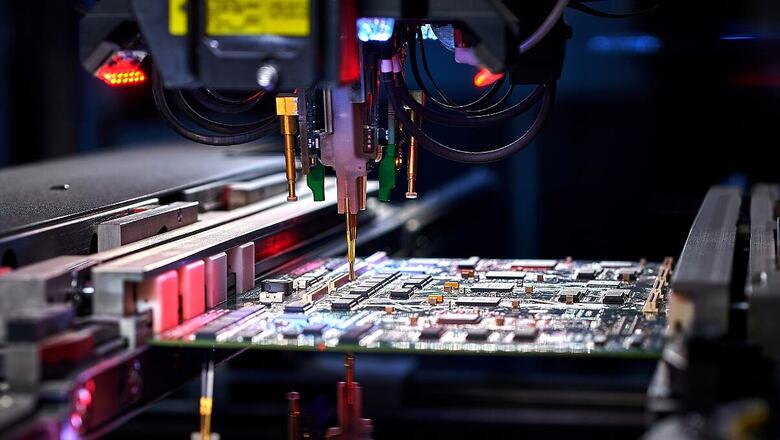

The integrated circuit (IC), commonly known as a ‘chip’ or ‘semiconductor’, is the fundamental building block of a wide range of modern technologies. From smartphones and medical devices to artificial intelligence (AI), quantum computing, space exploration, atomic energy, and telecommunications, semiconductors power critical advancements across industries. This innovation-driven sector has fuelled the Fourth Industrial Revolution, merging human ingenuity with the capabilities of machines.

Globally, semiconductors rank as the fourth most traded product, following crude oil, refined oil, and automobiles, underscoring their immense economic and technological significance.

India has recognised the potential of this industry and stands on the cusp of a transformative era, poised to become a global hub for semiconductor manufacturing. Under the leadership of Prime Minister Narendra Modi, India has unveiled an ambitious roadmap to position itself at the forefront of this vital industry. This initiative is more than just a push for economic growth; it represents a strategic move towards technological self-reliance and sustainable development. This guide explores the country’s efforts to expand its semiconductor industry and its quest to emerge as a leading global player in this critical field.

India’s journey to becoming a semiconductor powerhouse took a decisive step with the launch of the India Semiconductor Mission (ISM). This initiative aims to build a robust ecosystem for semiconductor and display manufacturing, driving growth in key areas such as silicon semiconductor fabs, display fabs, compound semiconductors, sensors, and semiconductor packaging. The ISM seeks to establish a thriving design and innovation environment, positioning India as a global leader in electronics manufacturing. By focusing on long-term strategies to develop cutting-edge manufacturing facilities, a secure supply chain, and essential intellectual property, the mission aims to fuel sustained innovation in the semiconductor industry.

In its pursuit of becoming a global semiconductor powerhouse, India has established several key facilities. These include a chip fabrication unit in Dholera, Gujarat, and four assembly and testing plants, known in the industry as ATMPs (Assembly, Testing, Marking, and Packaging) or OSATs (Outsourced Semiconductor Assembly and Testing). Three of these plants are located in Sanand, Gujarat, while the other, situated in Morigaon, Assam, is the nation’s first indigenous semiconductor assembly and testing facility. Its location in the hitherto neglected Northeast speaks volumes.

Apart from these, the Maharashtra government recently approved a major semiconductor manufacturing project, a joint venture between Israel’s Tower Semiconductor and the Adani Group, to be established in Panvel, Raigad district. With a substantial investment of Rs 83,947 crore, the project will initially have a production capacity of 40,000 wafers per month in Phase 1, scaling up to 80,000 wafers per month in Phase 2. Once operational, this facility will become India’s second chip manufacturing plant and the sixth semiconductor facility involved in silicon chip production or testing, further bolstering the nation’s semiconductor ambitions.

So far, the Indian government has approved projects amounting to Rs 1.5 lakh crore under the India Semiconductor Mission. The Union Budget 2024-25 further strengthens support for the semiconductor industry, including targeted incentives for MSMEs, which are expected to play a crucial role in the semiconductor supply chain by providing vital components and services. The budget also emphasises the development of industrial parks with plug-and-play facilities across 100 major cities, designed to serve as innovation hubs and accelerate the establishment of semiconductor manufacturing units. These efforts are part of the broader ‘Development of Semiconductors and Display Manufacturing Ecosystems in India’ initiative, backed by an allocation of Rs 76,000 crore. This comprehensive programme highlights the government’s commitment to building a self-reliant semiconductor industry and positioning India as a global leader in the sector.

India’s push toward semiconductor manufacturing is also closely aligned with its green energy initiatives. The roadmap includes key projects such as green hydrogen, electric vehicles, and small nuclear reactors, all of which aim to provide a sustainable energy foundation for semiconductor manufacturing.

By reducing the carbon footprint of these facilities, India is working to meet global sustainability targets while fostering technological growth. Equally critical to this growth are semiconductor design services, which involve creating detailed blueprints for semiconductor devices to ensure they meet specific performance requirements. Semiconductor design and development services take this process further, overseeing everything from initial concept to final product creation. These services are pivotal in driving innovation in semiconductor technology and enhancing existing designs, ultimately boosting India’s competitiveness in the global market.

International reports from leading firms such as KPMG, PwC, EY, and Deloitte underscore the rapid growth of India’s semiconductor market. According to a KPMG report, “India is home to 20 per cent of the world’s semiconductor design workforce, supported by a fast-evolving technology landscape and a robust domestic market—key factors driving the development of a homegrown semiconductor ecosystem.” These insights emphasise India’s potential to become a significant player in the global semiconductor industry. Programmes like the recently held SEMICON India, which supports companies in semiconductor designing, manufacturing, and packaging, are bolstering the semiconductor industry.

The Covid pandemic and the China-Taiwan conflict exposed vulnerabilities in the global semiconductor supply chain, leading to disruptions in industries such as automotive, electronics, and medical devices. This crisis sparked a shift in global strategy to diversify chip production, with India emerging as a key player in these efforts. India’s ambitious semiconductor manufacturing plans are poised to reshape its economic landscape.

The nation is also set to capitalise on the Australia-India Economic Cooperation and Trade Agreement (ECTA) and enhance the bilateral Critical Minerals Investment Partnership. This strategy will secure a steady supply of essential raw materials needed for both front-end and back-end semiconductor manufacturing processes.

As the world contends with semiconductor shortages and seeks more robust supply chains, India is strategically positioned to emerge as a major player in the global semiconductor market. This initiative is designed not only to address India’s increasing semiconductor needs but also to enhance the global supply chain, bolstering its role in future-focused industries. India’s commitment to semiconductor manufacturing represents a crucial step toward economic self-reliance and sustainable development, with significant long-term global implications.

Tuhin A Sinha is a national spokesperson of BJP, besides being an acclaimed author; Nishant Kumar Hota is a political and policy consultant. Views expressed in the above piece are personal and solely that of the author. They do not necessarily reflect News18’s views.

Comments

0 comment