views

X

Research source

Be aware that a permanent structural ramp will require engineering and/or carpentry skills and may require additional building permits, whereas a temporary/portable ramp can be fairly easily constructed on your own. Whether you or someone you know is disabled and needs a ramp for domestic use, or you're a business owner who needs to facilitate easy access to your building, learning how to build a wheelchair ramp can help make your building accessible and compliant with ADA regulations.

Planning the Ramp

Decide on the ramp's longevity. Before you inquire with your local building code office about whether you need a permit or begin gathering your materials, you'll need to decide on whether the ramp will be a temporary structure or a permanent addition on to the building. A temporary/portable ramp (which will be discussed in greater length) is much easier to construct, whereas a permanent ramp may require professional services and additional government oversight. It is worth noting, however, that in some communities a permit is required regardless of the structure's longevity.

Plan the location. If there is any chance you will need a building permit, it's best to have a plan drawn up to show your property lines, the size and location of your home, and where the ramp will be placed. You should also include the height, length, and width of the ramp, as well as its distance from the sidewalk or street. These plans may be required before securing a building permit in some communities. Even if such a plan is not required, it will be helpful for you to have for your own planning and records-keeping. In some communities, you may need a plan designed by a professional engineer or carpenter in order to secure a permit. Check with your local building code office to determine what (if any) documentation is required.

Estimate the cost. In addition to the cost of supplies and building materials, as well as any contractor or carpenter fees, you may have to pay for a building permit. In many cities and counties in the U.S., the cost of a building permit is determined by the estimated cost of building the ramp. In Erie, PA, for example, there is a flat rate permit fee of $29 if the project will cost under $2,000, but if it is in excess of that amount the fee is increased to $29 + an additional $6 for every $1,000 in excess of $2,000. If you are building a temporary/portable ramp, you may be able to simply estimate the cost of wood and any other necessary supplies. If you are building a permanent fixture, this may require the skills of a carpenter or engineer, which could significantly increase the estimated costs of construction.

Secure a building permit. In some places, a municipal building permit is required before construction of a wheelchair ramp may take place. This varies significantly from one municipality to another. Within the U.S. alone, there are considerable differences from one city to another. For example, in St. Louis, MO, wheelchair ramps are exempt from building permits if the ramp is laid down over existing stairs or is otherwise not permanently attached to the house. But in Erie, PA, all wheelchair ramps require a city permit that will cost approximately $29 or more, depending on the cost of the ramp. In cities where a building permit is required, you may face significant fines or other legal troubles for failing to secure a building permit before beginning construction of the ramp. Search online for your city and county regulations on building permits. You can also call your local Public Works office or a similar building code office in your city/county to learn about building permits and any local regulations that govern wheelchair ramps.

Measuring the Materials

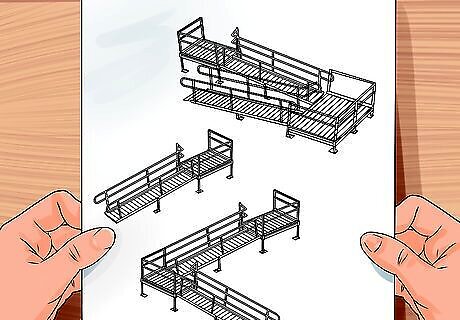

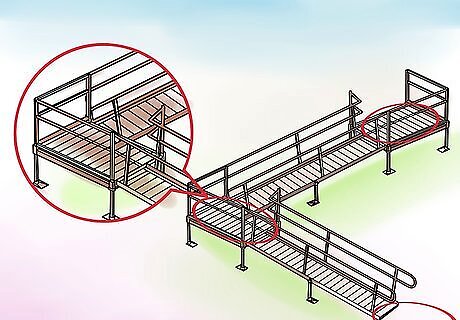

Choose a shape/layout. There are three primary ramp layouts that most builders choose. The first is a straight (also called an in-line) ramp, which incorporates the ramp and any necessary landings in a straight line. The second is an L-shaped (also called a dog-legged) ramp, which bends at a 90 degree angle at the intermediate landing. If the L-shaped ramp wraps around the house, it may also be referred to as a "wrap-around" ramp. The third is a switchback ramp, which incorporates a 180-degree turn at one or more intermediate landings. One of the biggest factors in choosing a layout for the ramp is visual aesthetics. However, sometimes the size and shape of your yard may determine the shape and layout of your ramp.

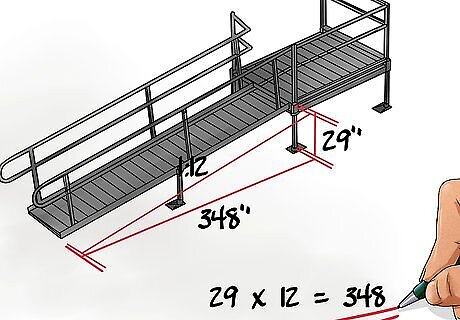

Provide a sufficient slope. The ramp's slope, or angle of incline, is determined by how much rise the structure must accommodate. For many structures, the ramp must have a minimum ratio of 1:12. That means that for every inch of vertical rise, the ramp extends 12 inches outward. This is to ensure that the ramp is not too steep and can be easily ascended and descended safely by the individual who will be using it. To calculate your estimated length of ramp, measure the total rise and multiply that measurement by the total slope chosen for your ramp. For example, a ramp with a 1:12 slope built for a 29 inch rise would be 348 inches, or 29 feet (29 x 12 = 348). Ramps may have a gentler angle than 1:12 - for example, extending the ramp 16 inches outward for every one inch of vertical rise (1:16) - to improve safety and ease of access. Ramps should not have a slope that is any less than 12 inches of run for every inch of vertical rise, though, as anything steeper than this may lead to accidents and/or injuries. Please note that if the ramp is for a commercial/business facility, your city, county, or state may dictate a separate slope requirement for indoor vs. outdoor ramps. In Minnesota, for example, interior or covered ramps for public/commercial use may have a slope of 1:12, but exterior ramps (which may be considered "walks," depending on your municipal codes) must have gentler slopes of at least 1:20.

Factor in landings. Depending on the size, angle, and primary use of your ramp (someone pushing a wheelchair vs. someone in a wheelchair transporting herself, for example), you may need to include landings on your ramp. There are three primary types of landings for a wheelchair ramp: a top landing, a bottom landing, and an optional intermediate landing. Top landings should measure at least 60 inches by 60 inches for an out-swinging door. The landing should provide at least 12 to 24 inches of "elbow room" on the handle side of the door, to ensure that the person opening the door can swing the wheelchair around and open the door without rolling backwards. This landing should come flush against the threshold of the exterior door, but it is recommended that there be no greater than a 1/2 inch gap between the ramp and the door threshold. This is to prevent the smaller front wheels from getting stuck, and to prevent walkers from tripping as they enter/exit the dwelling. Intermediate landings are typically optional, depending on the length and slope of the ramp. The size of this landing can range from 36 to 60 inches, depending on the slope. A steeper slope (such as a slope of 1:12) may require a longer distance in which the wheelchair may be stopped while descending. Bottom landings should measure at least the width of the ramp by approximately 48 inches of length if the ramp will be used by a walker, or 60 to 72 inches of length if the ramp will be used primarily by a wheelchair user. Make sure the bottom landing and ground are as close to flush as possible. A "lip" that measures more than 1/2 inch will pose a significant risk of tripping (for pedestrians) or rolling (for chair operators). Many experts recommend bolting the top landing to the building's foundation. Otherwise there will be a risk of the ramp lifting up from temperature fluctuations, which may pose a threat to the individual(s) using the ramp and could at the very least cause an out-swinging door to become jammed.

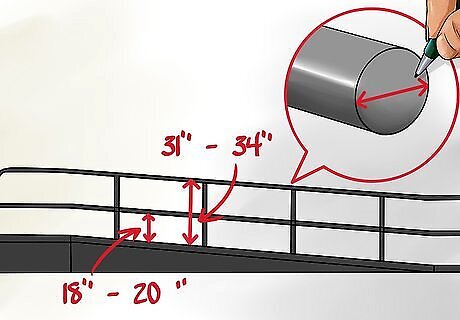

Add on safety features. Additional safety features like handrails and guardrails are an important component of most wheelchair ramps. A handrail can help prevent a wheelchair operator from falling out of the chair or rolling down the ramp, and a guardrail can help prevent the wheelchair operator from slipping off the ramp or landing. Handrail size and placement will depend on the height and arm strength of the primary user(s), as well as any local building code requirements that may be applicable to your structure. The typical height range of most handrail locations is between 31 and 34 inches. The width of the handrails should be less than or equal to 1.5 inches in diameter to ensure that the user can adequately grip the handrail. The diameter should be even smaller for children or adults with an impaired ability to grip or hold. Many lumber yards sell ready-made vertical hand rails. Guardrails should be mounted level with the primary user's seated knee height. This typically falls somewhere around 18 to 20 inches, though it's best to measure the primary user's seated knee height to ensure that the guardrails are effective and safe. Consider adding on a roof and/or gutters if the ramp is close to the building. Water runoff from the roof of the building may create a slipping hazard for wheelchair users, and a roof/covering will also help protect the wheelchair operator from the elements. An alternate option is to build a small extension off the roof to protect the ramp from runoff.

Building the Ramp

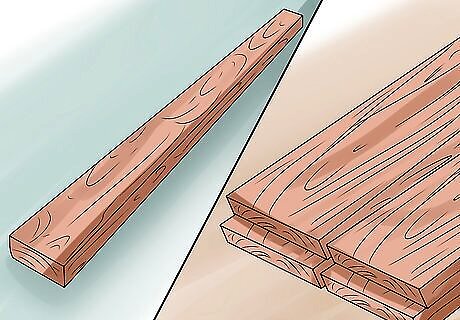

Use treated lumber only. Treated lumber is more durable and will weather precipitation and seasonal changes far better than untreated lumber. Even if the structure is a temporary one, it is considered a standard of ramp design to use treated lumber for the safety of the operator and the durability of the structure. It's generally best to choose medium-length lumber. For 2x4 and 2x6 boards, that means 16 feet or less in length. For 4x4 posts, choose beams that are 10 feet or less in length.

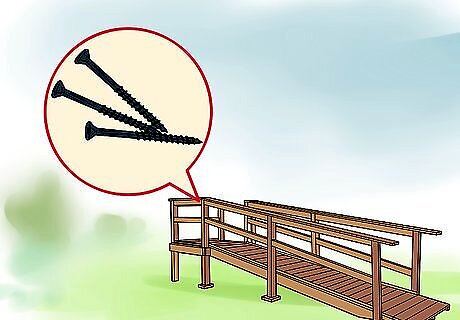

Build the ramp with screws. Nails can potentially come undone with time and use, which could cause a safety hazard. For a stable, durable wheelchair ramp that won't come undone, use screws to assemble the ramp. Nails should only be used for joist hangers.

Dig posts for permanent ramp. If building a permanent structure, you'll need to dig post holes to properly stabilize and secure the ramp. The posts themselves should be four inches by four inches in size (4x4), and should be spaced no more than eight feet apart, with six feet being the ideal spacing. Cross-brace each post in at least one position in each direction. This will help give lateral stability to the posts. Attach stringers to the posts using 3.5 inch screws. Use 1/4 inch by 4 inch high shear strength screws at each load joint and to fasten the sill to the home. If the stringers are not at ground level or very close to it, use joist hangers on the stringers. To secure these, use hanger nails 1 and 5/8 inch. For all other fastenings, use screws instead of nails to ensure a stable structure.

Lay down an anti-slip surface. Some municipal codes require an anti-slip running surface that extends the entire length of the ramp. Even if this precaution is not required, it is still highly recommended by building and safety experts. There are many options for creating an anti-slip surface, and the option you choose may depend on personal preferences. For wooden ramps, you can use a commercial "grit" tape, strips of roofing or shingling, or a coating of polyurethane sprinkled with sand. All of these materials are available at most hardware or building supply stores. For a concrete ramp, you can create an anti-slip surface by brushing the concrete with a broom while the concrete is still drying/hardening to create a rougher, less-smooth texture.

Comments

0 comment