views

Pulling Clogs from the Nozzle

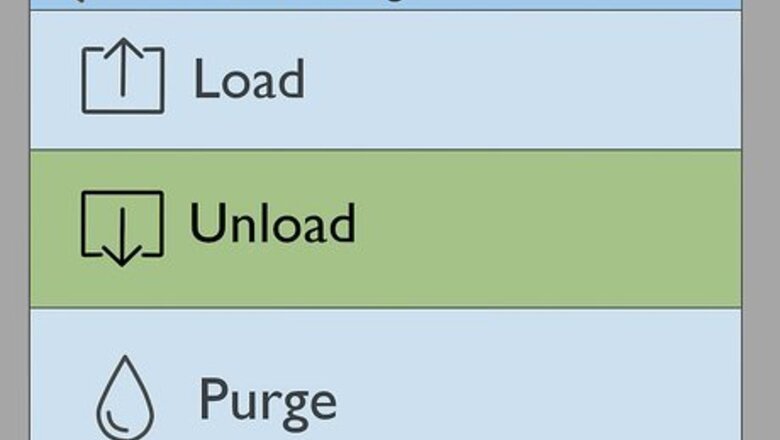

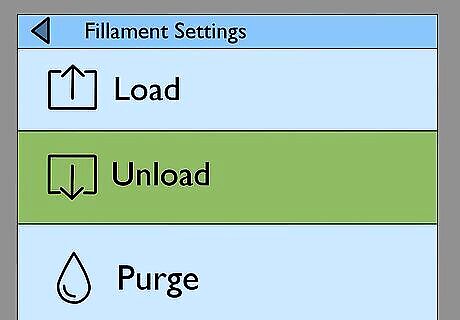

Unload the filament currently in your printer. Look for the “Unload” option on your 3D printer’s menu or the program you use to run it. Once you select it, wait until the nozzle heats up before pulling out the filament. Slowly pull out the filament so you don’t damage your machine. If your filament doesn’t come out, heat up the nozzle more until you can pull it easily.

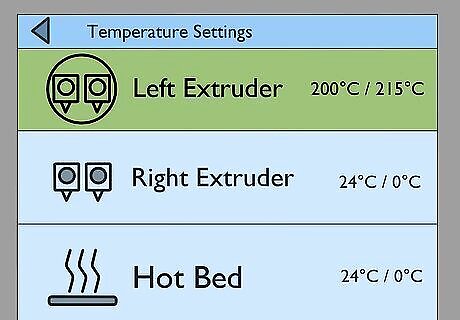

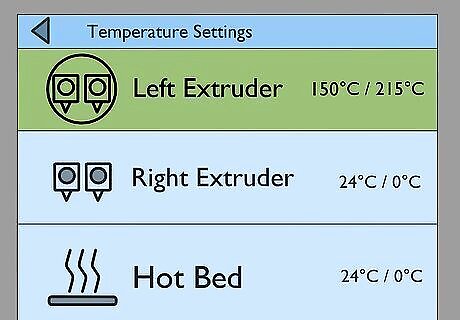

Preheat the nozzle to 200 °C (392 °F). After the filament is unloaded, the nozzle will start to cool down on its own. Go into your printer settings and start heating the nozzle to about 200 °C (392 °F). This will help loosen any leftover filament that could be clogging the nozzle. Let the nozzle heat completely before moving on.Tip: 3D printers allow you to adjust the heat settings in multiple parts of the machine. Make sure you’re only heating the nozzle while you clean it.

Push a clear ABS or nylon filament into the nozzle and hold it for 10-15 seconds. ABS plastic and nylon have high melting points so it’s easier to control to pick up clogs. Feed the end of the filament into the hole on top of your nozzle. Push the filament as far as you can through the nozzle until it stops. Keep the filament there for about 10-15 seconds so it has a chance to melt slightly. Avoid using any materials that have a lower melting point since they won’t retain their shape as well.

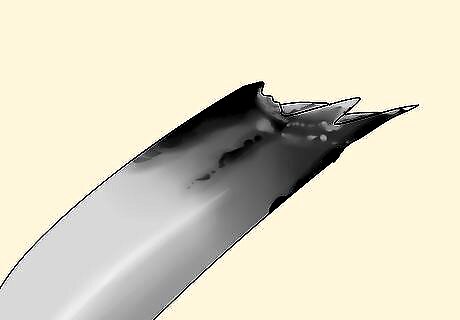

Pull out the filament and check for dirt before cutting the end off. After 10-15 seconds, quickly pull the filament back out of the nozzle. Since the ABS or nylon is clear and melted slightly, you should easily see any residue that was pulled out of your nozzle. Cut about 5 cm (2.0 in) from the dirty end of the filament with a pair of scissors or snips.

Repeat the process until the filament comes out clean. Continue putting the end of the filament into your nozzle and pulling it out after 15 seconds. As you keep working, the filament should pull up less dirt and grime. Keep cleaning the nozzle until the filament is clear when you pull it out. Always cut the dirty end off of the filament so you don’t put it back in your nozzle.

Doing a Deep Clean with Acetone

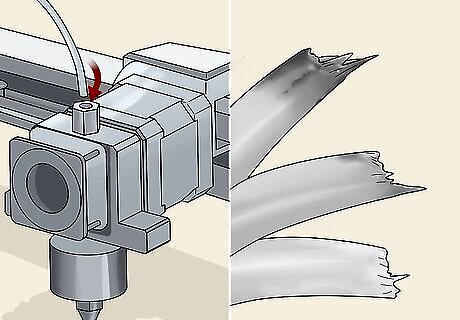

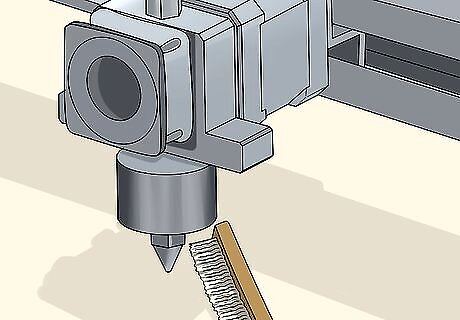

Scrub any stuck-on material on the outside with a wire brush. Leave your nozzle on your printer so it’s held securely. Work in back-and-forth motions and apply firm pressure with your brush to scrape any filament residue off. Change the angle and direction of your brush as you work. Wire brushes can be purchased from your local hardware store. Check the nozzle’s packaging to see if it’s safe to use a metal brush on it.

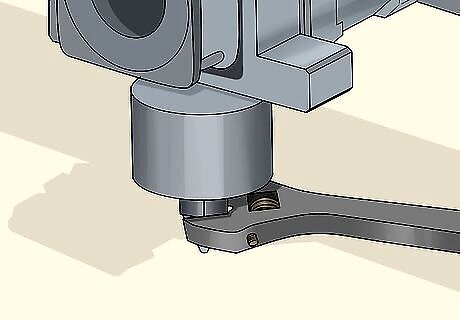

Heat the nozzle to 150 °C (302 °F). Heating the nozzle helps loosen the threads and make it easier to remove. Set the temperature to at least 150 °C (302 °F) so the metal can expand. Removing a nozzle cold could damage the threads and make it more difficult to screw back on.

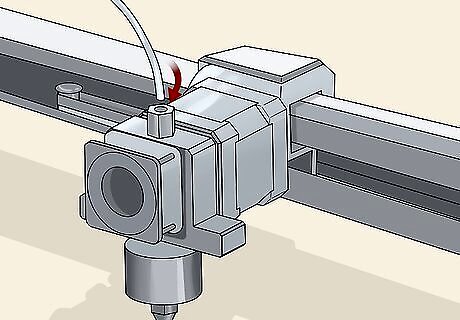

Remove the nozzle with a wrench. Once the nozzle is heated, secure a wrench to the nozzle and rotate it counterclockwise to remove it. Set the nozzle on a surface that won’t get damaged by the heat. Don’t touch the nozzle with your bare hands or else you will get burned.

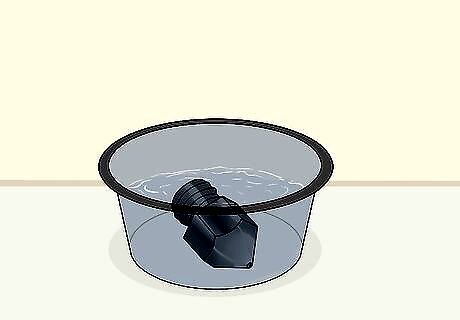

Submerge the nozzle in acetone for 15 minutes before drying it. Fill a container with enough acetone so your nozzle is completely submerged. Leave the nozzle alone for 15 minutes so the acetone has time to break down. Then, take the nozzle out of the acetone and dry it with a lint-free cloth or paper towel. Acetone is commonly used as nail polish remover and can be purchased at your local drugstore. The acetone helps loosen the dirt and grime on the outside of your nozzle as well as breaks apart the filament inside.

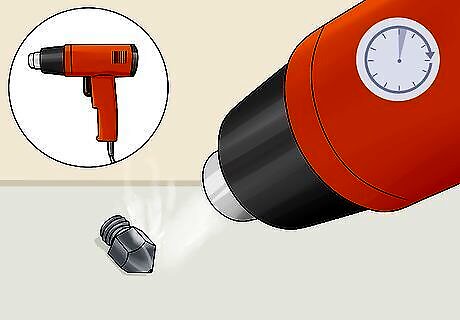

Heat the nozzle with a heat gun for 1 minute. Set a heat gun so it’s pointing straight up and turn it on. Grab the nozzle with a pair of pliers and hold it directly above the heating unit. Let the nozzle heat up completely, rotating it around so it’s evenly distributed. At this time, any filament residue should loosen up more. After 1 minute, turn the heat gun off and set it aside. Heat guns can be bought from hardware stores. Don’t point the heat gun directly at anyone since it could cause burns over time.

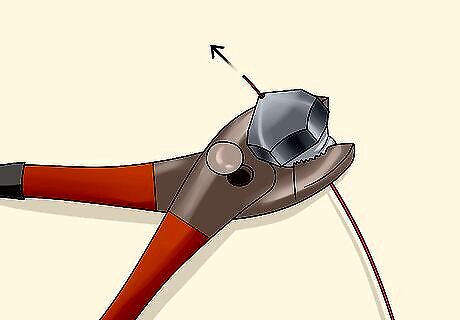

Push any clog through the nozzle with a thin wire or needle. Keep a firm grip on the nozzle with your pliers while you poke a wire or needle into the nozzle. Scrape the sides on the inside of the nozzle to remove any residue. Continue cleaning the nozzle until the clog is removed and you can see through it. Wipe the wire or needles clean whenever there’s residue stuck on them.Tip: If the nozzle still isn’t clean after 2-3 minutes, heat it again so the filament doesn’t solidify again.

Comments

0 comment