views

Repairing Hairline Cracks and Small Holes

Assess whether your hole or crack is ⁄2 inch (1.3 cm) diameter or less. This includes damage like punctures or screw holes. If the damage is this small, you can proceed with a simple repair with epoxy and no additional fiberglass sheeting. Push around the damaged area to feel for weakness in the fiberglass. A small spot of damage on the surface can actually be larger underneath. If the area that feels weak is larger than ⁄2 inch (1.3 cm), it's better to do a more intensive repair.

Put on personal protective equipment. This includes gloves, eye protection, and a dust mask or respirator. It is most important to keep fiberglass dust out of your lungs and eyes. You also want to keep it off of your skin if possible, as it can cause irritation.

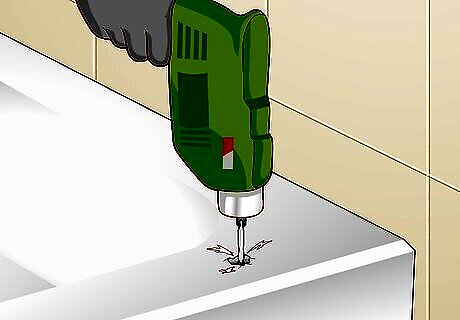

Drill out the damaged fiberglass. In order for the epoxy repair material to attach to the fiberglass and material underneath it, you need to drill out the damaged material. Use a ⁄4 inch (0.64 cm) drill bit and make a series of holes along the crack. This will open up the damaged area so that your epoxy can get inside and bond. For example, if you have a tiny ⁄2 inch (1.3 cm) hairline crack, drill several ⁄4 inch (0.64 cm) holes along it with the drill bit.

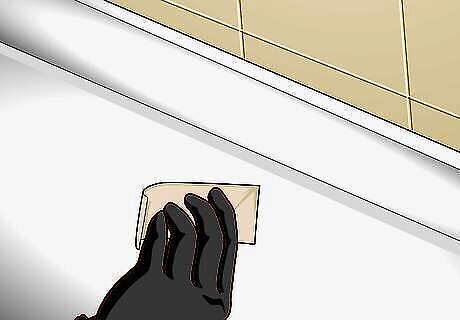

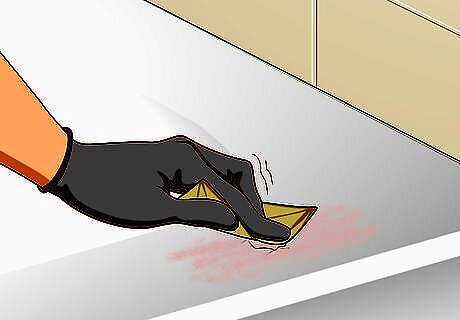

Wipe done the area with acetone. Cover a rag with acetone and wipe down the surface and the inside of the holes. Acetone is the cleaner of choice when dealing with fiberglass. It gets rid of all dirt and grime, as well as fiberglass dust, without leaving a residue. When using acetone, remember that it is highly flammable and needs to be used away from an open flame. The rag you use should be disposed of in a double bag in your garbage can. Acetone is available at most hardware and home improvement stores. You can also get it at pharmacies and big box stores in their nail care section, as it's most common use is as nail polish remover.

Cover the back of the hole with masking tape, if necessary. If you are repairing an area that you can get to the back of, block it off with tape so that the epoxy doesn't run right through it. Use any type of masking tape that you have on hand, as it just needs to hold for a small amount of time. In some situations, such as when you are repairing a bathtub, you won't be able to get to the back and that is fine. The epoxy will go down into the damaged area and you will need to use more to fill up the void but it will firm up quickly enough to fill the hole.

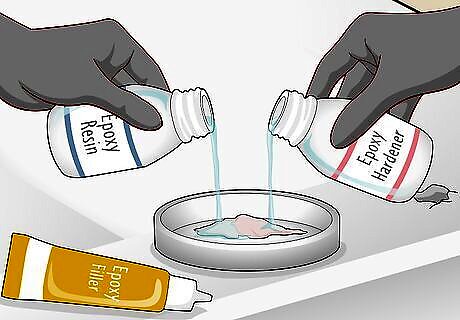

Mix epoxy resin, hardener, and filler together. In order to fill a small hole, you need a mixture of these three components. Consult the instructions that came with your epoxy resin to determine how much of each material you need. It is very important to get your proportions right, so follow the directions closely. Mix the epoxy in a disposable container with a disposable stirrer. Once the epoxy sets, the container and the stirrer will be coated with it permanently. The epoxy is the bulk of the material, the hardener causes the epoxy resin to firm up, and the filler makes the mixture thicker so that it doesn't drip right out of the repair area. These products are available from online retailers, marine supply companies, and some specialty hardware stores.Try to make about as much mixture as you think you will need to fill the hole while still keeping the proportions right. There is no need to make a ton of mixture when fixing a tiny hole.

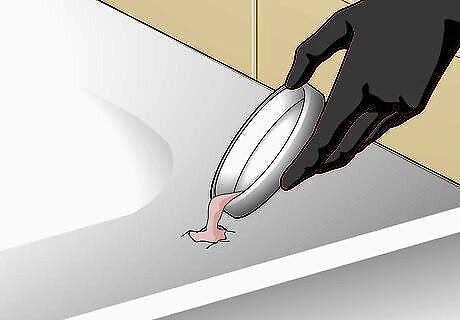

Pour the mixed epoxy into the hole until it is filled. How much epoxy you have to pour in depends on the hole and what is below it. If you have a solid surface underneath, it won't take much epoxy. However, if you have a hollow area, it may take quite a bit of epoxy. Try to keep the stream of epoxy small and slow so that you don't create a mess. If you run out of premixed epoxy before the hole is filled, don't worry. You can mix more and add onto the top as long as the previous batch is still tacky. If you overfill the hole or spill some epoxy outside of the hole, wipe it up with a rag right away. Then smooth out the surface. Wait 5 minutes and make sure the top of the epoxy stays level and doesn't slump. If it does slump, simply add more epoxy mix.

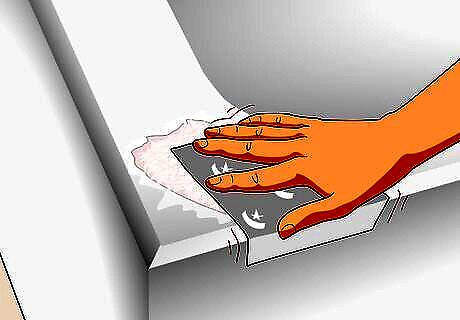

Sand the surface smooth once the epoxy has cured. Consult the curing directions on the epoxy packaging. Once the designated amount of time has passed, start smoothing out the patch area. Start with 80 grit sandpaper to get large areas of excess epoxy off. Then switch to 240 grit sandpaper to smooth out the surface. You can sand by hand or use an electric orbital sander, whichever you like.

Repairing Large Cracks and Holes

Put on personal protective equipment. This should include gloves, eye protection, and a dust mask or respirator. When repairing a large crack or hole you will be creating fiberglass dust, which shouldn't get into your lungs or eyes. You should also try to keep it off your skin as much as possible, as it can be irritating. Additionally, if you can do these repairs in a well-ventilated area, that is best.

Determine how much of the area is damaged. When an area that is larger than a ⁄2 inch (1.3 cm) is visibly damaged, you need to start your repair by assessing the true extent of the damage. Tap a coin around the area that is visibly damaged. You should be able to hear a difference in the sound made in areas that are damaged and areas that are not. Make pencil marks around the area that you think is damaged. This will help you keep track of what needs to be fixed.

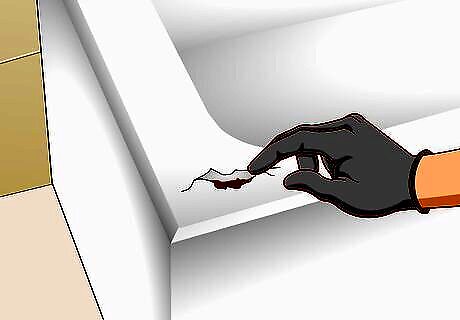

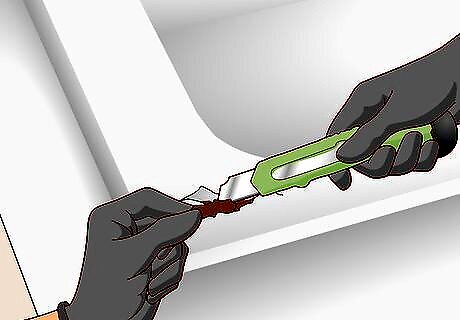

Clean out any damaged material. Open up the area that is damaged in order to understand the extent of the cracking and to prepare the area for repair. Remove loose areas with your fingers and pick off broken chunks with a utility knife or another pointed tool. Use a small ⁄4 inch (0.64 cm) drill bit to open up areas that are cracked through. This will allow the epoxy to get into the crack and adhere to it.Although you do need to open up the damaged area a bit, you don't want to increase the size of the damage during this process. With this in mind, be relatively gentle while still getting rid of broken pieces of fiberglass.

Sand down the area around the damage. Clean off any surface treatment on the damaged area and out beyond it at least 2 inches (5.1 cm) on every side. Use sandpaper or a sanding bit to take off the surface. This will ensure that all damaged material is removed and that there is plenty of surface area for your patch to adhere to. You can use a hand sander but an orbital sander or a sanding bit will be quicker for the amount of sanding that needs to be done on a larger crack. When sanding, you want to sand to the bottom of the damaged area and then taper up your sanding less and less as you move away from it. If you angle your sanding down towards the cracks, it will make your repair stronger and will allow you to make a smoother patch.

Clean the surface with acetone. After the surface is sanded down, you need to get everything off the surface so that the epoxy and fiberglass patch will stick. Use a rag or paper towel soaked in acetone to wipe down the entire area, including all of the internal edges of the fiberglass that you opened up. Clean 1 to 2 inches (2.5 to 5.1 cm) out past the area that you sanded so that all dust and debris are removed. Be careful when using acetone. It is highly flammable, so don't use it around an open flame. Acetone is a common product that is available at most hardware and home improvement stores. It can also be purchased at pharmacies and big box stores in the nail care section, as it's commonly used for removing nail polish.

Fill any holes with resin combined with filler. In order to create a base for your sheets of fiberglass to sit on, you need to fill any large holes or cracks with a base of epoxy.Mix your epoxy resin, hardener, and filler at the ratio suggested on the packaging. For filling gaps, the mix will have enough filler to create a product that is the consistency of peanut butter. The epoxy should be mixed in a disposable container with a disposable stirrer. How much epoxy you mix depends on the size of the crack you are filling. It's fine to make a guess and then if you don't mix enough, you can always make more while the first batch is setting. These supplies are typically available from online retailers, marine supply stores, and specialty hardware stores.

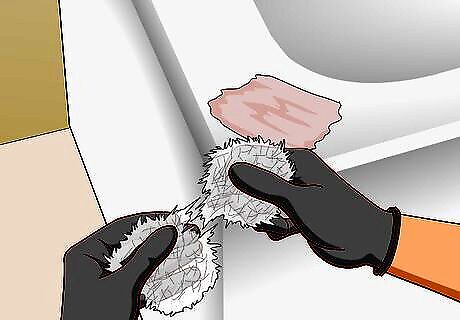

Tear out several pieces of fiberglass sheeting. Rip out the pieces of fiberglass sheeting in the shape of the area you are covering. Don't cut the pieces out with scissors. Ripping them will make a more subtle edge on the patch, which will make it easier to create a smooth transition. Be sure to wear your gloves and dust mask or respirator while ripping the fiberglass. Ripping it can create glass dust that could be inhaled if you don't have on personal protective equipment. Fiberglass sheeting is available from online suppliers and at many large home improvement stores.

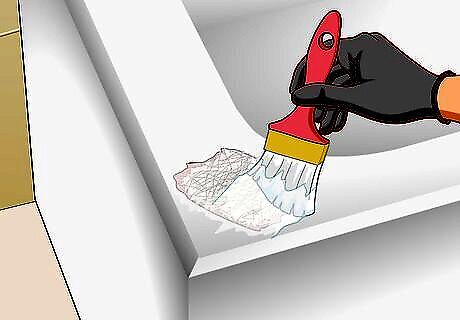

Use epoxy to attach the sheets of fiberglass. Mix a batch of epoxy and hardener. Brush on a layer over the entire area that needs to be repaired and then place one piece of fiberglass on top of it. Gently brush on another layer of epoxy and then set another piece of fiberglass on top of it. Layer the epoxy and fiberglass one more time, ending on a layer of epoxy. After you lay each layer of fiberglass down, use the tip of your brush to gently push it down into the surface. This will help eliminate air bubbles that might be stuck between layers. Smooth the surface as much as possible while it is wet. Look for imperfections and bubbles, which will show up in the finished product. Use the tip of your brush to pop any bubbles you see and to fill any voids.

Sand after the resin is fully cured. Follow the directions on the epoxy resin you used to determine how long the epoxy needs to set. In most cases, this will be about 24 hours. Once it is set, you can sand it smooth. Start with a rough sandpaper, such as 80 grit, to get large chunks of the resin off. Then use fine grit sandpaper, such as 240 grit, to make the surface totally smooth. It's important to let the resin cure long enough before sanding it so that it gets as strong and solid as possible.

Comments

0 comment