views

Getting Started

Learn your local building codes regarding roofs. Many building codes regulate the number of layers of shingles that may be on a roof, as well as what are acceptable shingling materials. Coastal areas that experience higher winds and hurricanes have different requirements for load and structural design than more centralized locations. If you live on the coast and want to roof your own house, you need to take extra care to obtain the proper permits to ensure the safety of your project.

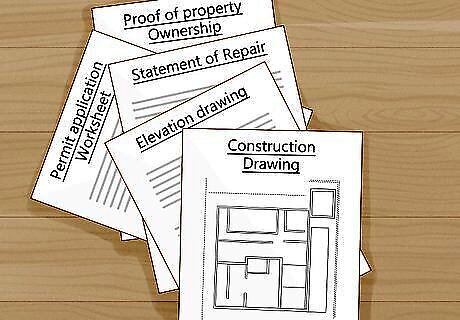

Obtain any necessary permits. Check with your local government agency regarding the need for a building permit before re-roofing your house. Permits are often offered by the Building Services Department of the city you live in. Generally, you'll be able to get the project approved over the counter if you provide: Proof of property ownership Permit application worksheet (provided) A statement of repair, stating that you'll replace the roof you remove to keep the building up to code Construction drawings Elevation drawings

Choose an appropriate kind of shingles. Shingles are available in many varieties, some of which are more appropriate for particular climates and roof styles. Pick something that works in your area, on your house, and with your particular style of project. Asphalt shingles are the most common type of roofing shingle. They're quite durable and can last for 20 or 30 years in the right conditions. Reinforced with fiberglass, asphalt shingles often feature dabs of roofing agent or tar that stick to the shingles above it. Slate shingles are the heaviest and most durable shingle you can buy. Because they break easily, require special pressure cutters to cut, and are about three times heavier than other shingles, using slate on your roofing project is only recommended if you're an experienced roofer looking for a challenge. Slate roofs are great if you want to create a unique and durable roof for your house and are willing to make the extra effort. Laminated shingles look somewhat like slate tiles, but are really layered asphalt shingles. They're similar, but somewhat thicker, to asphalt shingles, so working with them would be a similar project. If you like the look of slate, but want to make the job a bit easier, consider these types of shingles. Wood shingles are often hand-split shakes of cedar, spruce, or pine. Common in New England coastal regions, wood shingles allow for expansion and a natural weathering look that some people really enjoy. They need to be spaced slightly differently to account for expanding, but these types of shingles will typically last 30 years if installed properly.

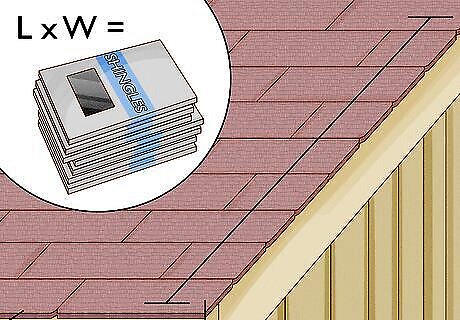

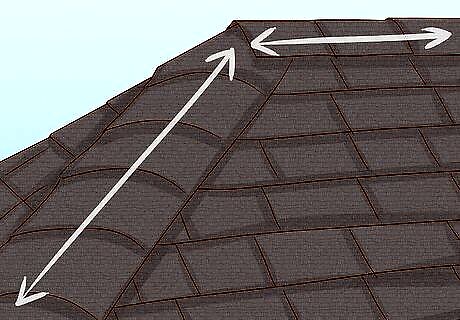

Determine how many shingles you need for the job. The surface area that shingles cover is defined as a square of 100 square feet (9.29 square meters). However, shingles are normally sold in bundles, with 3 bundles usually required to cover 1 square. To figure the number of bundles to purchase, measure the length and width of each section of the roof and multiply them together to get the area. Add the areas of each section together, then divide by 100 to get the number of squares the roof consists of. Multiply this number by 3 to get the number of bundles you'll need to buy.

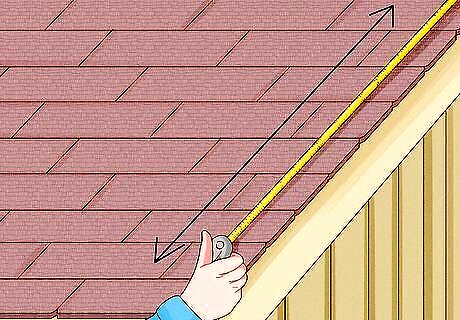

Measure the length of a shingle as it lies across the roof. This will help determine how the shingles will lay on the roof width. Most asphalt shingles are 3 feet (91.4 centimeters) in length. If your roof's width is not an even multiple of the shingle's length, you will have a partial piece on one end of each row. The bottom row of shingles must hang past the edge of the roof. For a wood shingle roof you would have to cut the shingles that go on the edge to create a straight line to accommodate this.

Preparing the Roof

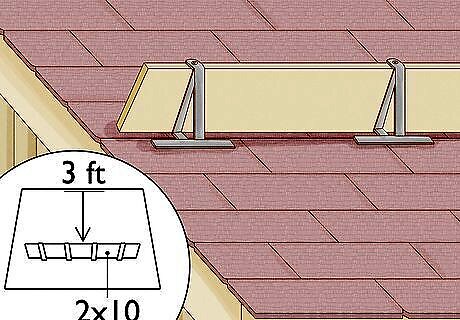

Take the proper safety precautions. Many roofs are at a high pitch and require roofing jacks to make the job safe. Scaffolding and toe boards help to secure the area on and around the roof to keep dropped tools and equipment from sliding off the roof and hitting passers-by. Set 2 x 10 jacks about 3 feet (0.9 m). up from the edge of the roof. Make sure you wear a good pair of rubber-soled boots to keep your traction while working on the roof. Work glasses and gloves are also useful.

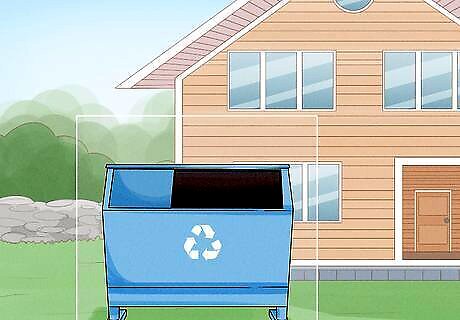

Rent a trash container. It's useful to rent a large trash container to throw the old shingles into. usually, this costs somewhere in the neighborhood of $200. If you keep it as close as possible to the house and cover AC units, porches, and other things you don't want to dent or litter with roofing nails and other debris, you can cut down on clean-up time later.

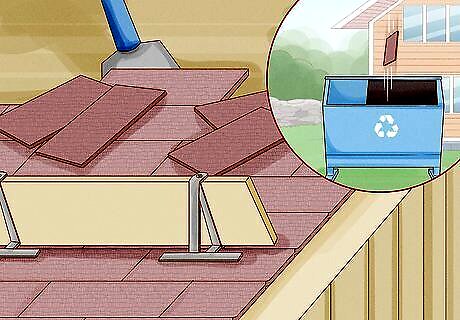

Start removing the shingles at the peak farthest from the trash container. Use a garden fork or a specially-designed roofing shovel to work your way under the shingles and pull them off more quickly, or you can go by hand and use a hammer. Pry up the nails, loosening the ridge caps first and then the shingles and shoveling them off toward the roof jacks. Take frequent breaks to shovel them off into the garbage. Don't worry about getting all the nails at first, some of them will come up with the shingles and some won't. This is usually the most physically-demanding and dirty part of the job, so make sure you plan for enough time and elbow grease to get it done. The shingles are often heavy and grimy, so don't let them pile up too much before shoveling them off the roof from the jacks and into the garbage. Be extremely careful with your footing and make sure to work in pairs. Consider investing in a safety harness if you're on a particularly tall roof.

Remove the metal flashing around chimneys, vents, and valleys in the roof. Some roofers will reuse the metal flashing if it's good shape, in which case you'd want to carefully remove the nails and pry it up. Flashing in the valleys is almost always trashed, though, so be judicious. Consider replacing all of it while you're in the middle of the project. If it looks suspect, toss it and install new flashing.

Clean the roof. Sweep the roof as clean as possible, taking the time to remove any stray nails that didn't come up in the removal of the shingles. Reattach loose boards in the sheathing. Examine the sheathing for damage and rotted boards, replacing the damaged sections accordingly.

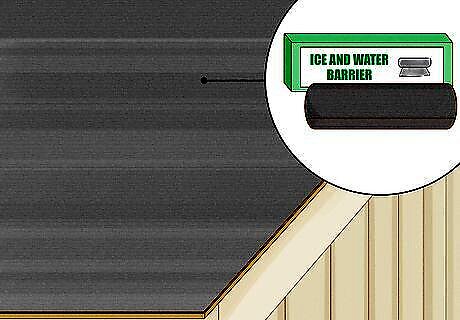

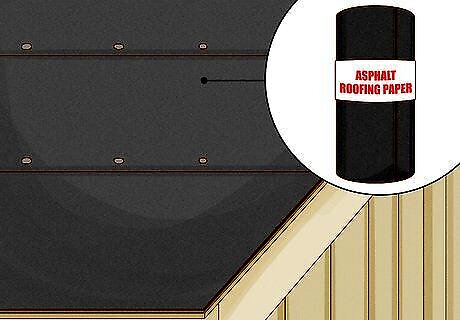

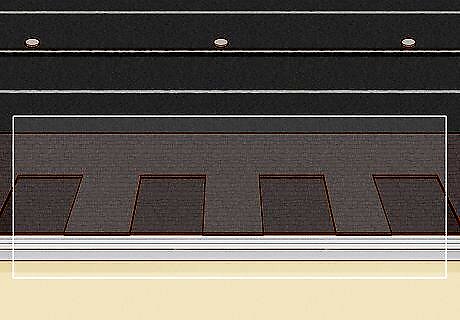

Install an ice and water barrier and asphalt felt. This underlayer will serve as a temporary weather barrier. If you have gutters, you'll want the ice and water barrier to cover all of the gutter flashing that's on the roof. Tack it at the top with staples every few feet to hold it in place. Once the entire section is tacked along the chalk line, lift up the bottom part, peel off the backing, then let it fall back into place. The ice and water barrier will immediately stick to the roof. Unroll and staple down 30-lb. felt over the rest of the roof. Use plenty of staples (5/16 in.) to make the felt safer to walk on and keep it from blowing off. This is where the hammer-type stapler (about $30) pays off.

Complete "weathering-in" your roof with the asphalt roofing paper. Use tin caps, approximately 2 inch (5 cm) round metal discs, under roofing nails to keep felt from tearing and blowing away, if there might be wind before shingles are put on. Keep the paper lined up straight by snapping a chalk line on the roof deck using marks measured up from the bottom. Do not use the bottom of the roof as a straight line. Doing so will most likely cause you to get the paper crooked, leaving you with wrinkles in the material. Allow the felt to extend 1/4 inch (6.5 mm) to 3/8 inch (1 cm) at the bottom roof edge.

Putting on the New Roof

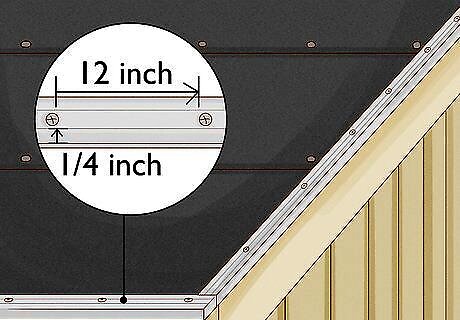

Mount drip molding around the perimeter of the roof. Use roofing nails, spaced 12-inches (30-cm) apart, extending 1/4 inch (6.5 mm) to 3/8 inch (1 cm) beyond the edge of the roof, over the felt paper.

Place the flashing in the valleys of the roof, where two sections create a valley. Nail this down as you did the drip molding. Flashing either comes premade, bent to fit or flat and ready to be cut. Some roofers like to salvage old flashing that's reusable. Valley flashing is almost always worn out, but use your judgment to see if it's still in good shape. Generally, you'll want to replace it.

Pop a series of chalk lines with 6-inch (15-cm) spacing. Use the chalk marks to maintain straight course lines for the shingles.

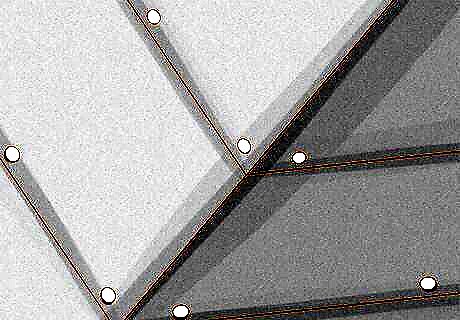

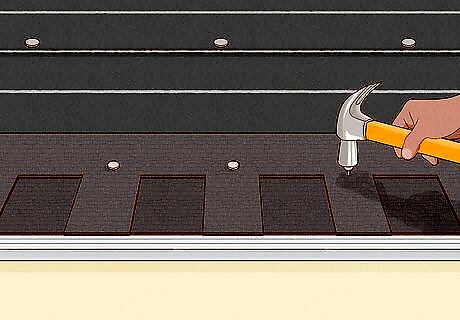

Lay the starter course. Follow the chalk lines, nailing your shingles down at intervals of 6 inches (15 cm). Space each nail 3 inches (7 cm) from the top edge of the shingle. Depending on the kind of shingles you purchase there may be a special starter row of shingles or a roll of strip material that you cut to the length of your roof. If you're using 3 tab shingles, put in your nails about 3/4 inch (1.8 centimeters) above the cutouts, near where the tab meets the upper part of the shingle. Also place a nail 2 inches from each end of the shingle, in line with the other two. In all, you'll use four nails for each 3-tab shingle to make them secure.

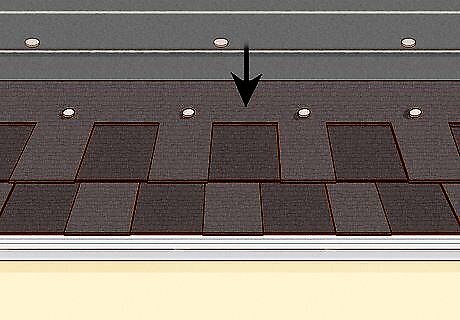

Lay the first course. Snap a horizontal chalk line over the starting row to use as a guide and remove the plastic strips on the back of the shingles in the package. Cut six inches off the length of the first starter shingle nailed on, then use the rest of them full size. Shifting them in this way will join the ends of the first regular row of shingles placed over the starter shingles. Alternatively, you can use a starting row of full-sized shingles by turning them with the tabs pointing upward.

Lay the second row of shingles. Set the first shingle of the second row back a half tab, 6 inches (17 centimeters), from the edge of first shingle on the first row and so that the bottom of its tabs just touches the tops of the cutout slots on the shingle below. This 1/2 tab has to be cut off where it hangs off the left edge of the gable roof. Continue laying your shingles in this same basic manner, trimming shingles to fit the extra space you leave at the end of each row. Leave space around vents, chimneys, and flashing to take extra time around those areas.

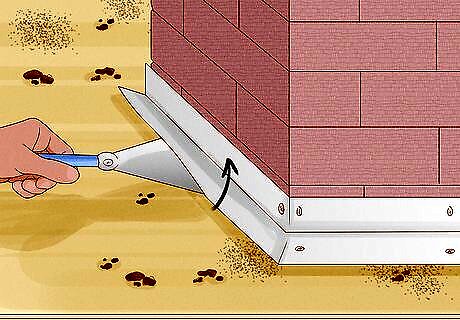

Shingle around vents and chimneys. Cut a square of flashing that extends about 6 inches from the pipe, with a hole in the center big enough for the pipe to fit through. Shingle over the flashing, using adhesive to hold it in place, and cut a special shingle to fit over the pipe and finish the job. Vent pipe "boots" (really just flashing) are available that you can slide over vent pipes, offering added protection. A rubber gasket makes it fit snugly and keep the joint from leaking. To shingle around chimneys, cut several strips of flashing to bend and create a joint between the wall of the chimney's outside edge and the roof. Install them into place normally and shingle up to the edge of the flashing. Use roofing adhesive and shingle over the flashing as normal.

Install preformed ridge shingles. Use roof adhesive cement at any exposed nails per manufacturer's instructions. Ridge shingles or caps are used to connect your courses on one side and the next, finishing the peaks with a uniform look. While pre-formed ridge caps are recommended, it's also possible to cut and form your own ridge shingles from regular three-tab shingles. Cut them to size and fold them over the peaks, installing as normal.

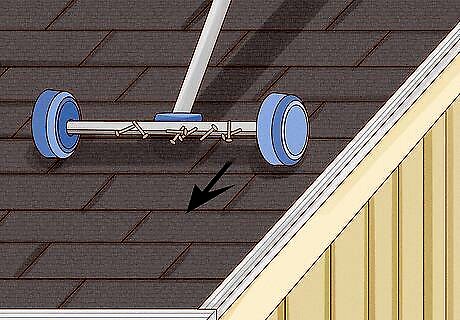

Finish the job. Roofing results in a lot of mess, so it's important to save enough time in the job to clean up sufficiently afterward. Nails, stray shingle pieces, and other debris will probably be littering the yard and surrounding area of the house, all of which can be dangerous if left laying around. Some roofers keep roller magnets (sort of like analog metal detectors) to roll around and pick up stray nails. You can sometimes rent these from roofing suppliers, or even borrow them for a couple of hours to make sure any dangerous nails are out of the way.

Maintaining Your Roof

Do a thorough inspection of your roof at least once a year. If you've gone to all the effort to put a new roof on your house properly, pencil in a regular inspection to make sure it stays up to snuff. Wait for warm weather days to inspect and also do an inspection after a period of rain to check for leaks or other issues. Especially in areas with high winds and nasty weather, it's very important for any homeowner to haul out the ladder and carefully check their roof.

Look for cracked caulk or rust on your flashing. Metal is especially susceptible to the elements. Examine any exposed flashing for signs that it might be wearing some and re-caulk any effected areas.

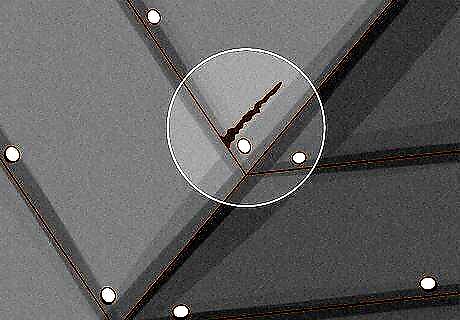

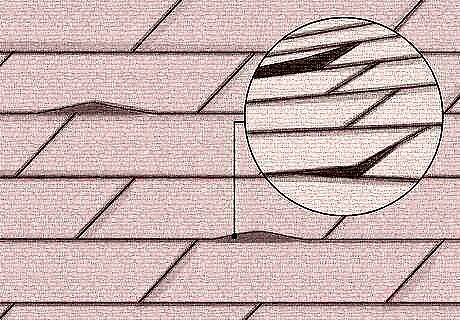

Look for curling shingles. Properly-laid shingles should stay relatively flush throughout their lifespan but will start to blister and curl up at the edges as they start to wear. This shouldn't be a problem for the first several years unless some of them were loosely installed. It's a good idea to go over and reattach any shingles that appear to be come up loose. Hammer any loose nails back, or pull them out and use new roofing nails to secure the shingles. Keep your roofing adhesive for patch-up jobs later on and add a little dab here and there where it's necessary. Seal any flashing you see coming up with caulk.

Eradicate your roof of moss. Mosses and lichens are the bane of the roof's existence. They harbor moisture and can decrease the life span of your shingles. Brush dead moss away with a broom and consider applying a commercial "moss killer" (usually in the neighborhood of $30) to the roof. For a natural alternative, sprinkle your roof with baking soda. Some moss killers have copper oxide or zinc that are harmful to the groundwater, not to mention pets and other animals. Sprinkling some baking soda on areas prone to moss build-up helps to keep the moss at bay.

Look for asphalt granules in the gutters. When your shingles start to wear out, you'll start seeing the little protective beads from the shingles come off in the rain and end up in the gutters. This is a sign that the shingles are nearing the end of their life span and will need to be replaced soon because they're no longer able to stand up to the sun's UV rays. Start planning for another re-roofing.

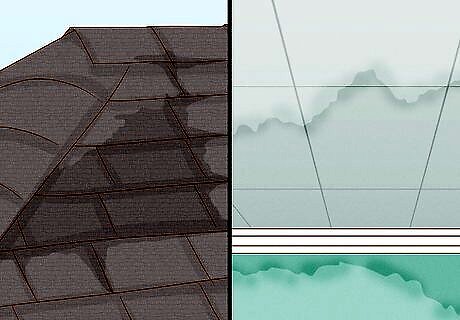

Watch for early signs of leakage. Inside your house, keep an eye out for signs that you might have a leak. It's best to catch it as early as possible before it becomes a major structural problem for your house. If you have a leak, consider getting a roofer's assessment and determine what fixes need to be made. Look for: Paint peeling under overhangs Damp or dark areas on the ceiling or around fireplaces Water stains around any vents

Comments

0 comment