views

Taking Safety Precautions

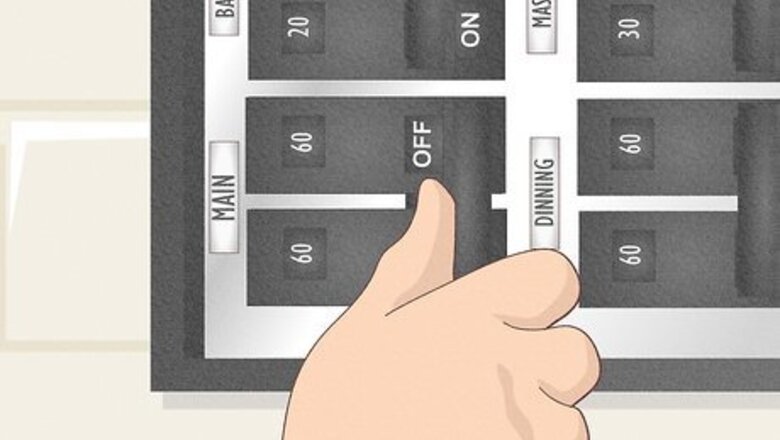

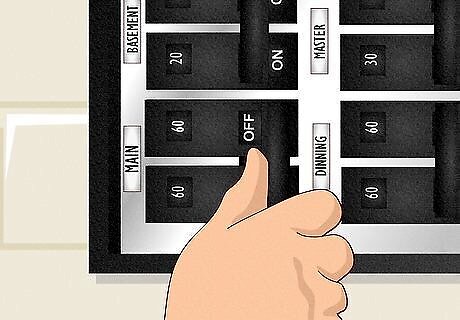

Turn off the main power. When working with a wire that’s already part of an electrical circuit, kill the power supply. Cutting the main power prevents the possibility of an accident. Find the main electrical panel for your home, which is often in the basement or lowest floor. Flip the main circuit breaker or unscrew the fuse to shut off the electricity. You can flip the main circuit or fuse to totally shut off power, or you can shut off power to the room you’ll be working in. You won’t need to contact the electrical company to work on wires in your home, although you can ask them to shut off (and turn back on) the power supply for you. However, they'll do this on their own time so be prepared to wait.

Test the circuit for voltage. Always double-check the wire to make sure it’s not carrying electricity. Get a multimeter, turn it to the voltage setting, and hook it up to the wire. If the readout doesn’t stay at zero volts, the circuit is still getting power. Shut off the power completely before trying to strip it. It's important to test for voltage, not current, because the multimeter may show a current reading of zero if no device is plugged into the circuit, even if power is still going to it.

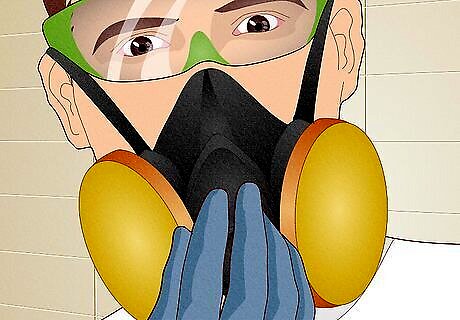

Wear protective gear. To further reduce the risk of accidents, wear safety gear. Put on a pair of eye goggles and rubber gloves. If there’s water on the ground, wear rubber boots as well.

Wear a respirator when working with a thermal stripper. Thermal wire strippers burn insulation, which can produce harmful fumes. Before using the device, put on a respirator. These masks can be found at any home improvement or general store. Alternatively, work in a well-ventilated environment in order to avoid breathing in the fumes.

Using Manual Wire Strippers

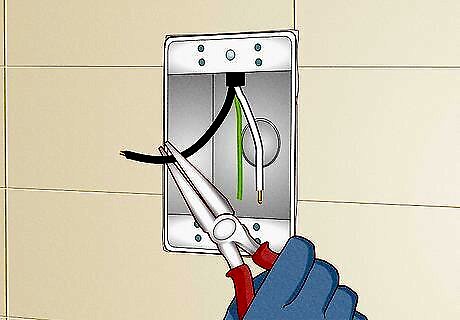

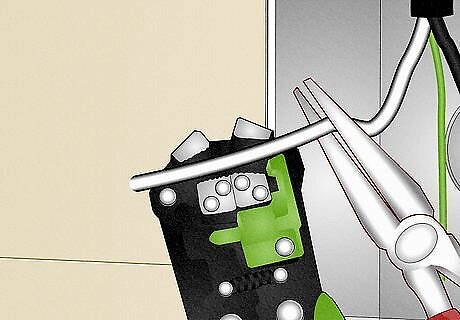

Pick up a pair of pliers. If the wire is attached to an electrical circuit, you’ll need electrical pliers. They’re identifiable by their protective rubber grips. For bending wires into tight spaces, needlenose pliers come in handy, while lineman’s pliers are for heavier wires. To figure out which type of pliers to use, look at the size of wire you’re stripping. Needlenose pliers are best for #12 wires or greater, which have a diameter of at least .08 inches (2.0 mm). Lineman’s pliers help with thick wires and may be useful for any bigger than than .08 inches (2.0 mm). If you’re stripping an unconnected wire, you’ll be fine using your hands.

Use the pliers to grip the wire. Hold the pliers in one hand. Squeeze the handles together to open the blades, then use them to hold the wire in place. Make sure you keep the wire away from any exposed skin, in case it’s energized.

Lay the wire between the stripper blades. Many manual strippers have notches for different wire sizes. Smaller diameter wires are handled closer to the tip of the blades. To get the perfect cut, use the pliers to feed the wire end into the proper slot. Test the notches until the wire fits snugly in one of them. Some strippers have a nut you can adjust to change the depth the of the cut.

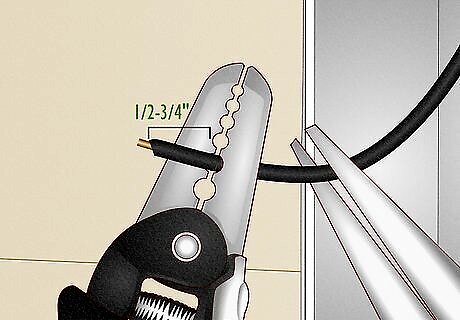

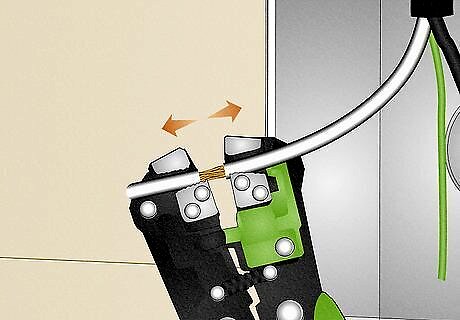

Set the stripper blades near the end of the wire. Move the blades about ⁄2 to ⁄4 inch (13 to 19 mm) from the end of the wire. This is typically all you’ll need to strip to attach the wire to a terminal or tie it to another wire. Adjust the blades to compensate when you need more or less wire than this. Strip more of the casing when you need to get to the underlying wire, such as when turning it to scrap metal or for science projects. When repairing a damaged wire, cut the wire under the damaged part and then strip the remaining wire ⁄2 to ⁄4 inch (13 to 19 mm) from the end. Removing too much insulation could create a short in the power box.

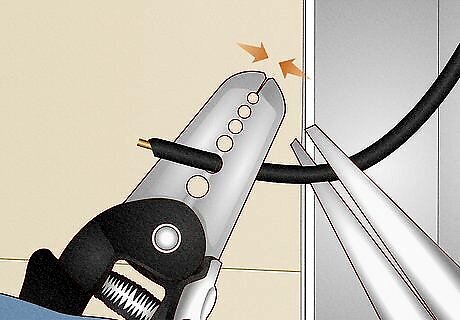

Squeeze the stripper blades together. Close the stripper blades against the wire, but don’t twist the wire. Instead, rotate the wire strippers in place. Once the blades have dug into the casing, pull the pliers towards the end of the wire. The casing should come right off.

Cut off any damaged part of the wire. Look out for wires that appear frayed or twisted or insulation that is damaged. These issues could create a short since the insulation keeps the wire from contacting other wires directly. Use the wire strippers to cut below the damaged part. You’ll need to strip the casing below the cut to expose a fresh piece of wire.

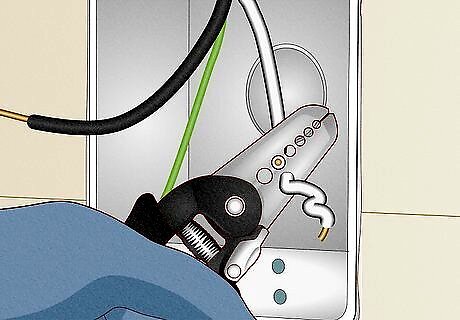

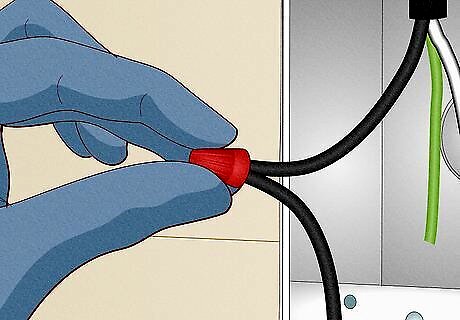

Splice 2 wires together, if necessary. After cutting out the bad section of wire and removing the insulation from both wires, twist the exposed sections together. Connect the two wires with a wire nut and make sure that no bare wire is showing beneath the nut.

Using Wire Stripper Machines

Use an automatic stripper to easily clip typical wire sizes. Manual pliers handle specific wire sizes. Automatic clippers handle these sizes and those in between them. These machines strip the wires cleanly with less manual effort.

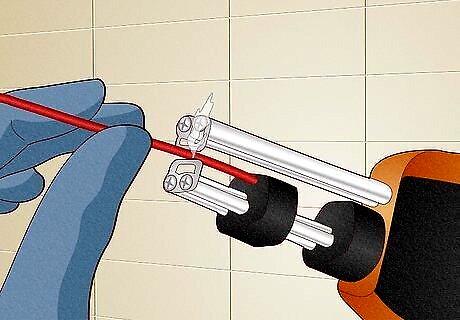

Place the end of the wire in the automatic stripper. Using your pliers, place the part you want to strip into the jaws of the automatic stripper. Wires that are very small or extremely thick still won’t fit and the machine will fail at cutting them.

Squeeze the automatic stripper’s handle. Press the handle together and the blades will cut into the casing at all sides. Pull the strippers up and off the end of the wire to remove the casing.

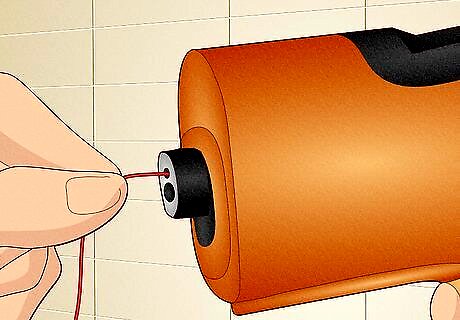

Use a laser wire stripper for extremely fine wires. Wires with a diameter less than .01 inches (0.25 mm) are very small and often made of fine materials. They’re too delicate to be handled by other strippers without taking damage. Instead, use a computer-controlled laser stripper to burn away the casing. All you do is set the wire in the machine and press a few buttons to operate it. You’ll have to search online and contact a company that makes laser wire strippers.

Get a thermal wire stripper for wires with thick insulation. Thermal strippers use heat to burn away insulation on wires with a diameter larger than .05 inches (1.3 mm). Hold the wire near the thermal tip of the machine and turn on the heat to cut through the casing. Only do this in a well-ventilated area, though, since the process will produce noxious fumes. You can usually find low-end thermal strippers online or in some home improvement stores.

Comments

0 comment