views

Building the Backstand Pipe

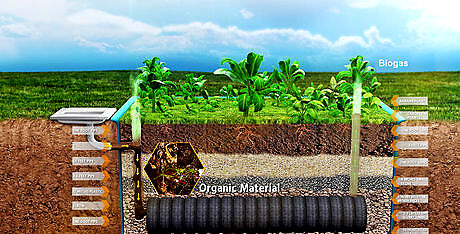

Understand the structure of the toilet. The evapotranspiration toilet has an impermeable, underground tank filled with layers of materials, decreasing in size with each rising, successive layer. Together the substructure layers use the anaerobic digestion, capillary action, evaporation, and transpiration processes to filter, release and absorb the waste matter. Anaerobic digestion converts a portion of the human excreta into biogas, exiting out the pipes. The digested matter travels up and out the tank through capillary action. The nutrients leave the system by incorporating into the plants’ biomass through mineralization and absorption by the plants’ roots, while evapotranspiration removes the liquid, either transpiring through the plants or evaporating at the surface from the soil.

Build the backstand pipe. Collect 15 recycled tires (size 12-13 or with a 2-foot diameter), and make a 4-inch hole in one tire. Cut one piece of pipe to 4 feet 6 inches and insert this pipe into the tire with the hole. No need to use sealant.

Prepare the rest of the pipe. Cut one piece of 2 feet, One piece of 2 feet 6 inches, and two pieces of 1 foot each.

Connect one 2-foot-6-inch pipe on one side of the elbow with the sealant. Next, connect the 1-foot pipe on the other side of the elbow with the sealant.

Connect the bottom of the T to the elbow pipe – the top of the 2 foot 6-inch pipe, using sealant. The top of the T connects to a one 1-foot pipe, using sealant. The middle of the T connects to the 2-foot pipe with sealant.

Make sure the finished pipe looks like this.

Digging the Hole for the Tank

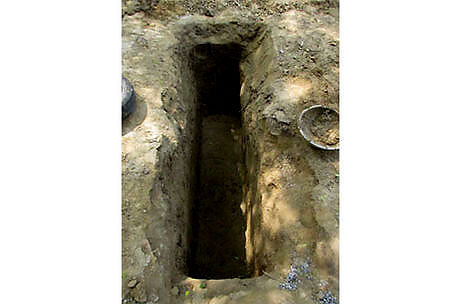

Dig the hole. Make it 9 feet long, 2 feet wide and 5 feet deep. Make sure not to dig the hole near a water source and not to dig the tank too wide, so that the width of the tank holds the tire in place. Confirm the location of the toilet seat at the beginning to properly align the toilet seat with the pipes and tires.

Line the tank. Use either with ferrocement, cement, a thick plastic sheeting, and/or two to four layers of slurry. One option is to create a plastic lining in the tank that completely covers the tank. Cut three pieces of plastic sheeting that are 3 meters long and 1.5 meters wide, and two pieces that are 1 meter long by 1.5 meters wide. Slurry lining option: Slurry_lining.jpg Plastic lining option: 3 plastic lining IMG_4382.jpg Brick lining option: IMG 20141117 WA006.jpg

Finishing the Tank

Create a four-inch layer with locally available, eco-friendly, inexpensive, big porous stones. For example, you can use broken bricks.

Create a single line of perpendicular tires. Start loading the tires from the front side of the tank. The one foot pipe connected to the elbow goes into the tank – into the tire duct. Use a jute bag, or some variation, to cover the tire’s hole and the front pipe. Secure with big porous stones / broken bricks. 5 tires in the tank start seat side confirm where you wnat the seat to position the pipe IMG_0451.jpg

Continue placing the tires, making sure they are perpendicular, aligning the holes of the tires to create a duct. The second to last tire is the backstand pipe (tire with hole and large pipe).

Place the last tire in and use a jute bags or some variation to cover its hole and secure with broken bricks.

Add 10 cubic feet of big porous stones. Cover and fill around the tire duct with broken bricks, around the border to secure the tires’ position.

Cover with some soil to protect the tank from small stones and other small materials.

Add 10 cubic feet small stones.

Add 20 cubic feet red-grey sand mixed, balu - morang layer.

Fill in the tank with soil. Make the land even.

Plant all the plants between both the pipes, directly on top of the tank. For example, use five Banana Plants, three Money Plants, and two Chia Plants. Choose any compatible, tall, large-leaf, high water plants. Do not grow any vegetables low to the ground, like spinach, etc.

Use your toilet. Once your plant layer has matured, it should look like this.

Comments

0 comment