views

Choosing a Blade

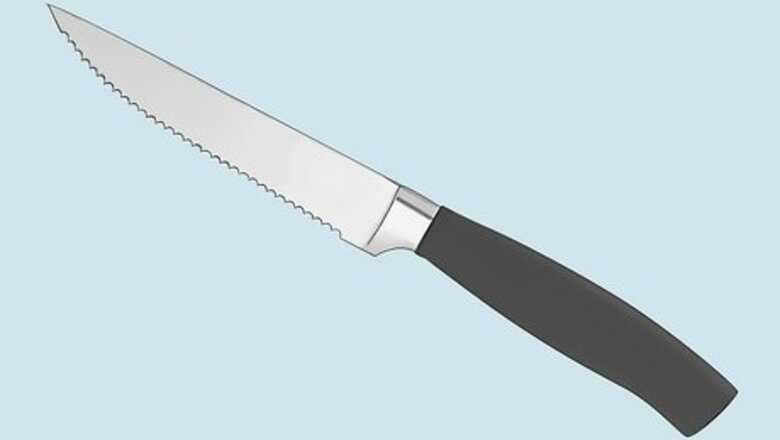

Use a long serrated knife to easily cut thick foam. Small air holes form inside the foam when it's heated, similar to the air pockets that are created inside bread when it's baked. That's what gives foam its light, airy consistency—and it's also why it can be hard to cut. If you use a serrated knife like the kind used for cutting bread, it will make the job much easier. This works best for foam that's at least 2 in (5.1 cm) thick. Ideally, the blade of the knife should be longer than the thickness of the foam. That will make it much easier to slice all the way through. You may have better control over a long knife than some of the other options, so this might be a good choice if you need to make detailed cuts.

Get speedy cuts in thick foam by using an electric kitchen knife. If you happen to have an electric knife (like the kind used for carving turkey), you can use that to quickly and easily trim your foam to size. These are especially handy if you'll be working on a large project or if you need to cut the foam at an angle. When you're using an electric knife, it's a good idea to line up the foam so the line you're cutting is hanging off of your work table. That way, the edge of the knife won't make contact with the surface while you're cutting. If your foam is less than about 2 in (5.1 cm), it's probably easier to use a rotary cutter or craft knife. You can purchase electric kitchen knives at most department stores. They're usually pretty inexpensive, so it might be worth picking one up if you have a big project to work on.

Opt for a rotary cutter to cut thin foam pieces. If your foam pad is ⁄2 in (1.3 cm) or less, a large (60mm) rotary cutter can make short work of the job. Simply mark where you want to cut the foam, then roll the blade over the line you made. Rotary cutters can be useful for cutting curved lines, but they might not be ideal for intricate work. You could also use a box cutter for thinner foam, as long as the blade is about the width of the pad. Sharp scissors may work for this, as well. However, these aren't ideal for cutting thicker pads.

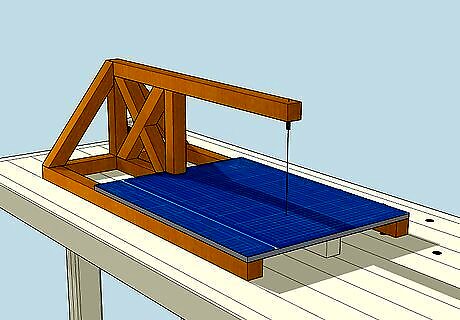

Try a hot wire cutter for horizontal cuts, but use caution. Hot wire can easily slice through foam, and many people prefer them if you need to cut large foam pads into horizontal slices. Hot wire cutters run an electrical current through a wire that's held taut by a frame, and you just have to push the wire through the foam. However, there's some concern that this technique might produce toxic fumes from heating up the foam, so be sure to work in a well-ventilated area if you choose this technique. In addition, if you move too slowly or you pause while you're cutting, you might melt the foam, causing it to harden and possibly become misshapen. Hot wire cutters are only safe to use on foam made of polystyrene and polyethylene. Do not use them to cut foam made of polyurethane—the fumes produced would be very toxic. Be very careful not to touch the wire—it will burn you.

Invest in a foam cutter if you'll be working with large quantities. Foam cutters have an electric blade that works similar to an electric kitchen knife. However, the blade is stationary, and it's mounted to a flat plate that slides underneath the foam. This makes it easier to create precise cuts, and you can easily create curved lines and detail work by turning the foam as you cut. Foam cutters are expensive, so if you just need something that will work for one project, it's probably not worth the cost.

Making the Cuts

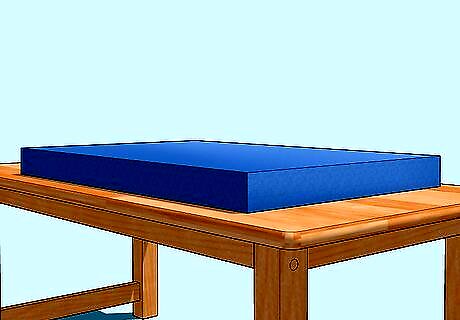

Place the foam on a covered, sturdy surface. Find an area that's big enough to hold your entire foam piece, like a large work table. Then, cover the table with a tarp, blanket, or towel. This will make cleanup easy, since the towel will help catch any small pieces of foam that fall off when you're cutting. Make sure you choose a surface that won't be damaged by a sharp blade or heat if you're using a hot wire cutter, like a wooden or metal table. If you don't have a table large enough to work from, place a sheet of plywood or a large sheet of flattened cardboard on the floor. This will protect the floor while catching any foam that falls. If the foam is hanging off of your work surface, the weight might cause the piece to shift while you're cutting. To protect your hands during this project, consider wearing cut-resistant gloves if you have them.

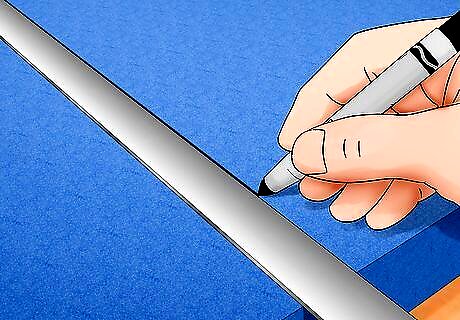

Mark your cuts with a permanent marker. Use the marker to trace the shape you want your finished foam pad to be, moving the tip lightly across the foam so you don't cut into the pad. To make a straight line, use a straight edge like a drywall square or a piece of cardboard. If the cuts will be more detailed, you might want to print out or draw a template and pin it to the foam before you trace your lines. If you'll be working with a thick piece of foam, you may want to mark your cuts on the top, sides, and bottom. That way, it will be easy to make sure your cuts are straight all the way through the pad. Remember, it's better to err on the side of cutting the pieces a little larger, rather than having them be too small. The foam will compress into place if it's a little too big, or you can cut off more if you need to. If you're cutting 2 shapes out of the same piece of foam, avoid having them share a side, just in case you make a mistake. For instance, if you're cutting 2 cushions from the same foam pad, you'd want to put a gap of at least 1–2 in (2.5–5.1 cm) between the squares.

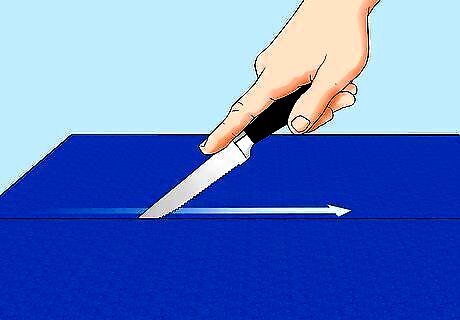

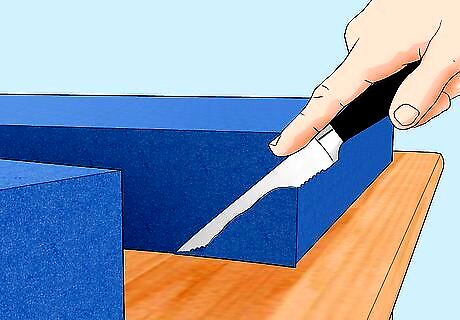

Score the foam along the marked line if you're using a blade. If you're using a knife, rotary cutter, or box cutter to cut the foam, hold the blade so it's perfectly vertical over the line you want to cut. Moving the knife away from your body, lightly drag the blade along the line you drew with firm, steady pressure. Create a shallow cut here—don't worry about trying to cut all the way through the foam. If you're using a serrated knife, you may need to make a gentle sawing motion with the knife blade as you cut through the foam. As long as the blade stays straight up-and-down, you should still get an even edge. If you're using a hot wire cutter, carefully push the wire through the foam in a steady, even motion. Don't stop moving the wire once you start cutting—otherwise, you could melt the foam. If you're making curved cuts, it might help to hold the knife up-and-down and cut from the side.

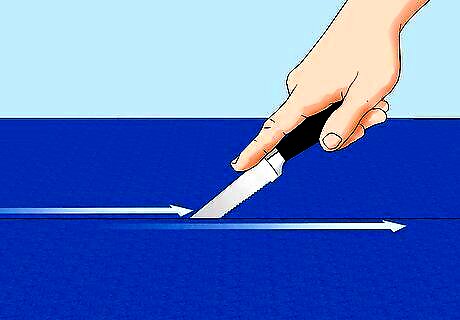

Continue making smooth cuts until you slice through the foam pad. Once you've scored the foam, continue running the blade along the mark you made. Each cut should as smooth of a motion as possible. Don't push down hard with the knife—just let the weight of the blade do the work on each pass. If you need to, make several passes until the knife slices through the bottom of the foam. Do not press down on the foam while you're cutting. That will change the shape of the foam, making your cuts uneven. If you're using a long enough knife blade, you should be able to easily cut through the bottom of the foam pad without having to compress the foam. Make gentle sawing motions if you're using a serrated knife, but don't press down hard.

Clean up any uneven cuts, if you'd like. If you kept your knife straight up and down on each cut, the foam should be cut cleanly. If there are any chunks or ragged pieces on the edge of the foam, however, you can use your knife to trim them away. If you're planning to cover the foam with fabric, a little bit of unevenness is probably fine.

Comments

0 comment