views

Before You Begin

Determine the type of trailer you'll need. A utility trailer should be customized to your specifications. You will need to decide on the length, the weight capacity, and whether or not it will be enclosed. For example: If the utility trailer will be used for lumber or building materials, it may need stronger suspension and larger wheels. For ease of loading and unloading—especially lumber—you would probably not want it enclosed. You would also want to make it long enough to hold lumber and sheeting. For machinery and valuable tools, you would not only want it sturdy, but also enclosed and secure to prevent theft. The vehicle that you will use to pull the utility trailer will also help determine the dimensions. For example, a utility trailer to haul groceries behind a bicycle will necessarily be much smaller than a utility trailer for a Suburban, built to haul a table saw.

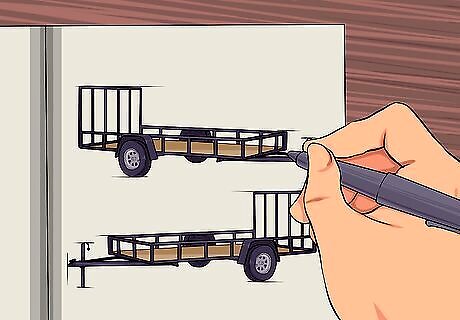

Decide the method of construction. You may choose to build a utility trailer from scratch or assemble a kit. Either way, the right tools and materials are essential. Search online websites for utility trailer kit plans or visit a home improvement store, or tractor supply dealer for ideas.

Confirm your level of ability. In the planning stages, it's important to be aware of your construction and mechanical expertise and capabilities. Building a utility trailer from scratch will require welding skills, an aptitude for carpentry, and electrical knowledge to install taillights. It also helps if you're comfortable with heavy lifting.

Assembling the Utility Trailer

Gather the materials and tools. Working according to a utility trailer plan will help you gather the right components. Once you have located a source for the materials, check with the customer service representative to arrange delivery. If you are a skilled welder and have the equipment you'll need, follow the manufacturer's recommended safety and procedural instructions. Most designs consist of a bed, a hitch, a "tongue" (the wedge shape that extends from the front), an axle with wheels, taillights, and a license plate frame. Many of the components for utility trailers (tongue, hitch, axle, jack, and taillight assembly) can be purchased fully assembled, allowing for easier construction.

Check local weight regulations regarding independent brakes. If you are building a trailer that is intended to carry heavy loads, it will need its own brakes. Not installing brakes on a heavy trailer can make it prone to jackknifing, and is illegal. If you are intending to use the trailer in multiple countries/states/provinces, check the local weight regulations in each region you are likely to visit. For example, in Canada, the weight cutoff varies from 910 kg to 4,500 kg, depending on the province.

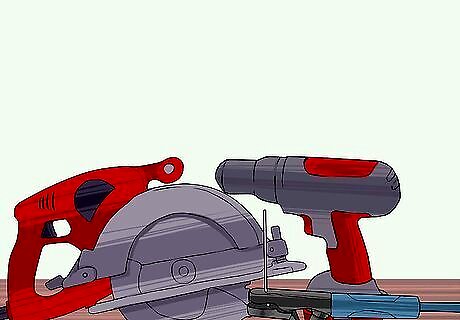

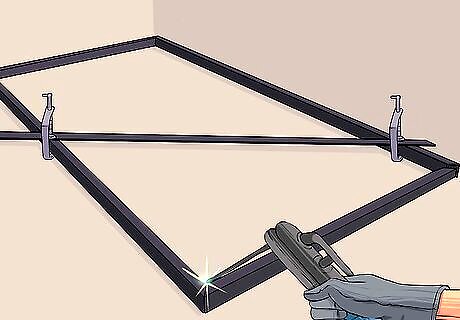

Construct the trailer frame. The frame will consist of 4 steel angle iron rods, 2 for the sides, and 2 for the front and back. Depending on the established length of the trailer, the sides might be longer than the front and back. Weld the angle iron rods together for the bed frame. Assure the corners are squared. Weld support beams made of flat iron across from side to side. Bolt pressure-treated 2x6 inch (5.1 X 15.2 cm) boards to the frame, parallel with the sides inside the lip of the angle iron. Cut lumber with a circular saw. Drill holes in the angle iron with a variable speed drill and drill-bit designed for metal. Attach boards to frame bed.

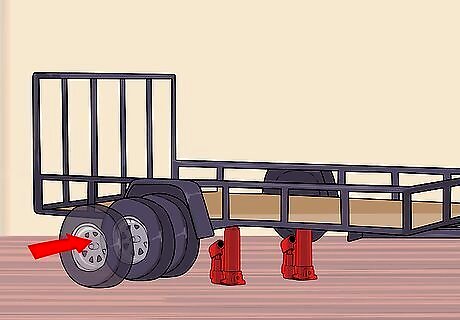

Attach the axle and tires. Use a hydraulic jack to raise up the frame. Block all 4 corners to keep it elevated. Weld the axle under the framing. On a rectangular frame, the axle should be attached with 60 percent of the frame in front and 40 percent in back to distribute the weight of the bed. Using the lug bolts and nuts included with the axle kit, install the predetermined sized tires on the axle.

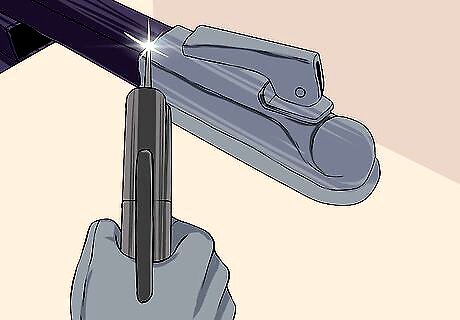

Finish out the other parts. Weld the hitch to the tongue and attach the assembly to the front of the frame. Attach the jack behind the hitch on the tongue. Route electrical wires from the front to the rear for the taillights. Assure the taillight connector is in front. The taillight assembly will consist of a combination of park, brake, and signal lights. The wiring harness should be secured under the trailer and the lights attached to rear with bolts on either side.

Comments

0 comment